igus® e-chainsystem® E4.1 - One for All

igus® E4 technologies and engineering for long service life, high stability, ease of installation and modularity

Save away many new costly additional components with the E4.1 e-chainsystem®.

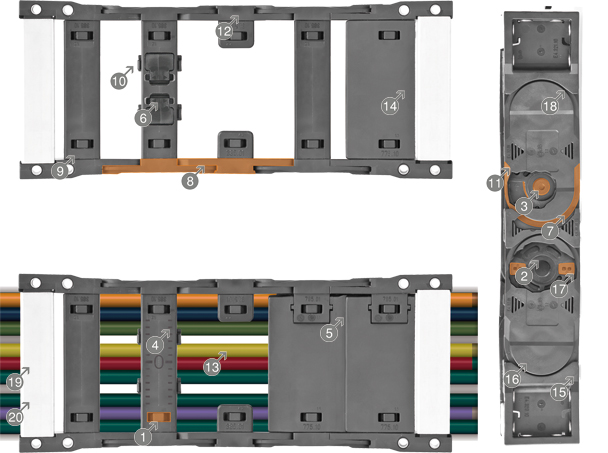

1... Double lock

Guaranteed high holding strength in simple, but secure opening mechanism... max. holding strength up to 2700 N

... can be quickly opened with screwdriver

Proven and extremely secure snap-open system. You loosen the crossbar by two simple lever movements. The crossbars thus reliably hold even with thick filling and can still be easily opened.

igus® tested

The max. holding strength of each crossbar is tested in practice with a tensile test. This can also take place under the influence of oil or other liquids.

Test 3577:Pull-out strength Cross bars:

> 2700 N

Application example

Side-mounted turned 90° with high filling. Crossbars hold securely and remain accessible.

2.1... Vertical, rectangular stop dogs

For maximum force absorption and thus high stability for large unsupported lengths... max. unsupported additional load possible up to 600 kg/m

... max. unsupported lengths (FLB) 8.0 m (+25% with the optional XXL material)

"In comparsion of the predecessor (igus® Systems E4/00 and E4/4): 25% more fill weight"

Details of working principle

More than two stop dogs cannot be, or can barely be synchronized. Due to a rectangular shape, the force distribution is much better than in a round stop dog (surface pressure formula, p = F/A). The complete E4.1 range has the double, rectangular stop dog.

igus® tested

We test every energy supply system with a "tweak testing machine" at the igus® laboratory for compressive/breaking strength to provide reliable specifications on max. additional load and unsupported length.

Application example

The tongue and groove of the e-chain® provides the high lateral stability, which was necessary for the high lateral acceleration of up to 8 m/s² through the X axis.

2.2... Vertical stop dogs, large pins

Better force distribution and thus higher push/pull forces and loads possible... push/pull forces up to 7000 N possible

... additional loads up to 600 kg/m and more possible

"In comparsion of the predecessor (igus® Systems E4/00): 20% longer free span"

Details of working principle

By shifting the stop dogs, the force is guided through three points, namely the two stop dogs and the large pin, instead of absorbing the force centrally. This reduces the load of the individual elements, pins und stop dogs, effectively to 1/3.

igus® tested

The max. load is tested over a period of 96 h. The photo shows an E4.1 with the optional material "XXL", with it the max. unsupported length can be further increased by +25% to approximately 7m.

Application example

This telescoping three-axle semi-trailer truck of Goldhofer AG, Memmingen is extendable from 20 to 62 meters. The design of the stop dogs and tongue and groove ensure that the energy chain® withstands 30 percent more pull/push forces.

3... Large pin/hole connection

High push/pull forces and less wear through precise tolerances... travels over 800 m possible

... accelerations of 10 m/s² and more

"In comparsion of the predecessor (igus® Systems E4/00 and E4/4): Ø 56% higher tensile strength"

Details of working principle

Large pin/hole connections with tight tolerance provide a high push and/or pull force absorption potential. Due to the tight tolerances and the resulting, almost complete zero backlash, very high accelerations can be achieved and there is very little wear.

igus® tested

We test every energy supply system with a "tweak testing machine" at the igus® laboratory for compressive/breaking strength to provide reliable specifications on max. additional load and unsupported length

Test 3992:More than 30.000 N tensile strength

Application example

travel of 615 m

The longest plastic distance in the world covered by an igus® E-Chain® was designed and delivered for the largest power supplier in the Czech Republic, the CEZ Group. The distance covered is 615 m.

The stable pin/hole connection enables such long travels thanks to high push/pull force absorption.

4... Scale on opening crossbars and option to engage separators

Simple pre-configuring with interior separation provides for a secure hold even in "side-mounted" applications... Simplifies fitting with interior separation elements, which can be clipped in place in 5 mm increments

... Completely level, no cable wear due to scale

Details of working principle

Scaling visible, but not "tangible". Standard for all E4 crossbars. Facilitates the pre-configuring with interior separators and thus saves valuable assembly time. Separators with projections can be placed in the opening crossbars in 5 mm increments and hold securely (approx. 25 kg retention force of the separator in the clipped-in position). No additional distance pieces necessary

igus® tested

In endurance test we test all chainflex® cables for wear and thus service life in continuously moving operation. We also test customer-specific cables, so that we can predict the service life of the system.

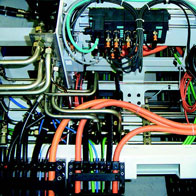

Application example

Numerous chainflex® cables neatly laid and mounted turned 90° in an E4 e-chain®. The interaction of energy chain® material and jacket material is a decisive factor for the service life.

5... Swivelable lids

For quick insertion of the cables from both sides... good access from top or bottom

... swivelable lid. Lid and bottom can be removed

Details of working principle

The lids of the enclosed R4.1 e-tubes can be easily flipped open and completely removed. This helps the easy insertion of cables. R4.1 e-tubes already close very tightly.

TEST> tightest igus® e-tubes IP tested:

igus® tested

Not only easy to open, but also extremely tight. Tests at the igus® laboratory show the high tightness of the e-tubes.

TESTA = igus® RX e-tube RX40.100.100 251,900 cycles

B = igus® e-tube 68.10.100.0

256,132 cycles

C = Testing tube 01 250.907 cycles

D = Testing tube 02* 2.600 cycles

*Test aborted after 2.600 cycles

Application example

Cables safely guided and protected from dirt and dust. In this application, an igus® snap-on clip for E4 was additionally installed to guide a hydraulic hose.

6... Quick-release crossbars

25% time saving through quick-release lock while opening and closing... holding strength up to 500 N tensile strength

... reduce assembly times by 25% - 80%

Details of working principle

"Nipple through the strap" system - two fastening straps on top of the crossbar can be unlocked manually or by screwdriver. Lateral "sliders" then release the crossbar from the side plate of the e-chain®

igus® tested

Opening in one workstep, no second step necessary. 25% faster assembly than standard crossbars. Even higher holding strength.

Application example

Good accessibility to the cables saves valuable assembly time. Not only when first filling the e-chain®, but also in case of a potential replacement during operation.

7... Tongue and groove

For high stability in lateral accelerations and high torsion through "interlocking"... additional loads of almost 7.7 kg on 2 m unsupported

... ideal for side-mounted applications or high torsional forces

Details of working principle

The chain links are "hooked into one another", which provides for extremely high torsional stability of the e-chain® and for high unsupported lengths even in side-mounted applications.

igus® tested

Here we also test every system for maximum load capacity to get reliable information on service life, which is also incorporated into our online service life predictor.

Test 4099:2 m E4 e-chain® with 7.7 kg additional load

Application example

An E4 e-chain® hangs unsupported on this reflecting telescope. The stable design and the tongue and groove provide for a safe energy supply system even in this installation type.

8... Inner/outer link design

For straight run and high parallelism and high stability... alternately inner and outer link provide for a very straight run

... exact parallelism of the e-chain® hinges support the durability

Details of working principle

igus® tested

Inner/outer link design in all E4.1 e-chains®.

Application example

Neatly guided in a guide trough with the same minimum clearances to the right and left. Important for the durability of the entire system.

9... Cable-friendly plastic crossbars

For even higher service life of the cables through rounded design... Cables have the longest durability with plastic crossbars

... no plastic deformation with external impact force

Details of working principle

Smooth, cable-friendly inner contour and rounded crossbars provide for a long service life of the cables and hoses. The combination of the tribo-optimized plastic of the crossbars with the jacket material of the used cables proves to be the best matching pair for the service life of cables in tests.

igus® tested

Cable wear in plastic crossbars: Jacket materials of different materials show the best wear results in plastic crossbars. Moreover, compared to aluminum crossbars, these are not subject to plastic deformation with external impact force.

Application example

Even in such rough applications, like here in a coal excavator, the wear naturally plays an important part. Among others hydraulic cables are guided in the e-chain® and a failure becomes really expensive.

10... Cable-friendly interior separation

For higher service life due to rounded base... nearly halve the cable wear

... less parts, more possibilities

Details of working principle

Smooth, cable-friendly and rounded contour provides for a long service life of the cables and hoses. In addition, a better and more cable-friendly interior separation can now be implemented with less standardized components.

igus® tested

With the new rounded separators, the wear of the cables could be almost halved.

Test 3748:Separator 301 compared to new version 45.1

The matching pair of plastic and jacket material also turns out to be the best here.

Application example

Here the rounded plastic crossbars assist in increasing the service life of cables

11... Sound brake

Dampens noise of the stop dog and rolling... Noise level from 33 dB(A) possible, 44 dB(A) measured with igus® E4 series

... many series certified by TÜV Rheinland

Details of working principle

Simple principle, but extremely effective. A wedge-shaped contour in the e-chain® stop dog dampens the stop dog noise of the e-chain®.

igus® tested

We test many igus® e-chains® for noise emissions in our own laboratory. We also get many series tested by the TÜV. Sound values of igus® e-chains® are, for instance, at 33 db(A) - 46 dB(A).

Test 4381:E4.32 with running noise below

44 db(A) stop dog noise, at 1 m/s

Application example

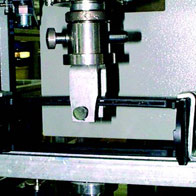

If the rolling noise needs to be reduced further, the optional dampening pads can help. A reduction up to 5 dB(A) is possible.

12... Wear pad

For long service life even on long travels... 10,000 km and more running performance is guaranteed

... for long travels and high service life

"In comparsion of the predecessor (igus® Systems E4/00 and E4/4): 30% more gliding surface"

Details of working principle

igus® tested

Every e-chain® achieves at least 10,000 km running performance on long travel - often much more. This is a "promise" that we've been fulfilling since years.

Application example

Reliably solve long travels with igus® e-chains®, like the E4 series here in a gantry crane, guided in an igus® guide trough for 220 m.

13... 1,030 chainflex® cables from stock

... from 1 m, no cutting costs, no minimum quantities

... chainflex® works or your money back

Details of working principle

Flexible cables in energy chains® or in robots require special features to survive many cycles, high speeds and accelerations as well as more demanding environmental conditions. EMC safety and the compliance with norms and guidelines such as NFPA 79, UL, CSA, VDE, Interbus and Profibus are also a necessary requirement today. The igus® chainflex® product range covers energy-chain friendly control cables, servo cables, motor cables, as well as robot cables and also bus cables, data cables, encoder cables and fiber optic cables

igus® tested

All chainflex® cables are always tested in practice. This means in the e-chain® or in motion, such as here in the igus® climate chamber at -40°C.

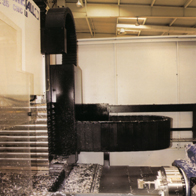

Application example

In this CNC multi-spindle lathe, every single working position must be securely supplied with media, energy and signals. High freedom of movement in all axes require a high durability and reliability of the cables.

14... Good protection against dirt and chips, even against hot chips

For the protection of your cable... hot chips up to 850°C cannot burn into it

... extremely tight and still easy to open

Details of working principle

igus® energy tubes to protect cables and hoses are already successfully used in the chip area since almost 20 years. Dust, dirt, oil, aggressive environments, humidity, cold and heat do not affect the rugged plastic energy supply systems. The optional HT material makes the 850°C hot chips just bounce off - no burn-in possible.

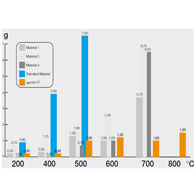

igus® tested

Test:20 g hot chips (200 to 850°C) applied on different materials. The graph shows which chip quantity was burnt-in. Winner: igumid HT up to 850°C.

Application example

High-temperature e-tube inside the machine guides and protects the cables in the hot chips area.

15... Wear allowance

Long service life, even for applications that are turned sideways... lateral wear pads provide for a long service life

... an important criterion, particularly in applications turned 90°

Details of working principle

igus® tested

Abrasion tests at the igus® laboratory. The service life of the e-chains® is tested in endurance tests.

Application example

400° rotary movement in a crane head. Thereby large circle diameters with high fill weights are possible.

16... Special contour of the links

Smooth-running due to soft unrolling... silent unrolling of the e-chain®, improved installation

Details of working principle

The contour provides for a better unrolling of the e-chain® and for a simpler and secure installation.

igus® tested

The contour of the chain links reduces the polygon effect and thus rolls smoothly. Even the "zigzag" installation type is thereby positively supported.

Application example

Here it should be as silent as possible. Large E4 e-chains® as zigzag application on a theater stage.

17... Without pretension

by simply rotating the exterior link... release with the same e-chain® version without pretension

... no (thermal) finishing, available from stock

Details of working principle

By simply rotating the outer links, an e-chain® with camber can be quickly converted into an NC version. NC versions are only required in special applications, for instance, in hanging application and crammed space conditions.

igus® tested

Special products, e.g. for storage and retrieval units, are also tested here, for instance the guidelok slimline F system that prevents the e-chains® from swinging out in storage and retrieval units.

Application example

Particularly in hanging installation or crammed space conditions, an e-chain® "without pretension" is the first choice.

18... Few parts, made from one material

Quickly assembled, high dynamics & and no differing material expansion... accelerations up to 784 m/s²

... same materials

Details of working principle

Few parts and all made from one material - important in high accelerations, as smallest possible clearance/few parts. Same material is optimal in material expansion/shrinking due to temperature differences

igus® tested

Even speeds up to 10 m/s and more are tested on the long-term at the igus® laboratory.

Application example

Extreme accelerations up to 784 m/s² require a precisely fitting and clearance-free energy supply system. This is guaranteed by the low number of parts.

19... Strain relief of electrical cables

Space reducing and reliable chainfix program... Three times higher tensile strength of igus® chainfix clamps

... also safe under the influence of oil, coolant, water

Details of working principle

Strain relief systems from igus® were specifically developed for the use in e-chains® and dynamic applications. The combination of chainflex® cable materials and the in-contact plastic components of the chainfix strain relief systems from igus® are designed for high cable durability and maximum holding force.

igus® tested

The tensile strength of the igus® chainfix clamp is more than thrice as high as the conventional strain relief systems.

Application example

Media, data and control cables are reliably and securely strain-relieved in this ready-to-install readychain® system for machine tools.

20... tight mounting bracket

... chip protection up to the front edge of the e-tube

... retrofittable with integrated C rail for the installation of a strain relief

Details of working principle

Retrofittable and very tight. With front mounting, the "tight KMA" keeps away dirt and chips all around.

igus® tested

With the tight "KMA" a last "gap" was closed in applications in the working environment of machine tools. The chip-proof plastic/metal mounting brackets with integrated C rails protect the cables up to the front edge of the e-chain®, while providing the possibility for strain relief at the same time (with the help of CFX strain relief clips).

Application example

Front flange-mounted with the "all-round" fastening KMA mounting bracket (KMA: plastic-metal connection)

21... Flexible modular kit

... bracket for hoses with diameter up to Ø 300 mm

... extension links for widths up to 3000 mm

Details of working principle

Available options from stock and extension for the E4.1 range.

igus® tested

Whether with extension links for widths up to 3.0 m, or bracket for hose diameters up to Ø 300 mm or more noise-dampening options, for instance "dampers" that can reduce the rolling noise of the e-chain® by up to 10 dB (A). The E4.1 system is highly flexible and adaptable to your application.

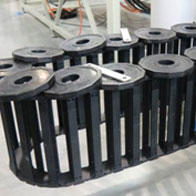

Application example

Series ES4.80 from the igus® E4.1 range as a noise-reduced version and extension links design

e-chain® system E4.1 for almost all applications

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!