Lubricant-free and precise deflection of conveyor belts

Precise and lubricant free deflection

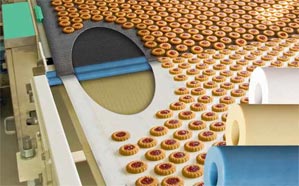

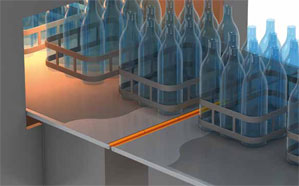

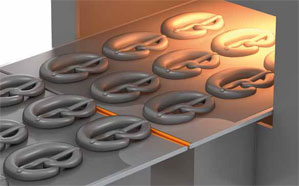

Application area: Packaging, conveyor technology, automation, food technology.

igus® has knife-edge conveyor belt rollers that were developed in-house for use by the conveyor industry for deflecting conveyor belts. Three iglidur® materials are available from the standard product range: the universally usable iglidur® P210 and the FDA compliant materials iglidur® A180 (up to 90°C) and iglidur® A350 (up to 180°C). The iglidur® solution is characterized by tight deflection radii and low essential driving power.

Complete freedom from the lubricant of the belt deflection

Low driving power

Tight deflection radii

Long service life of the belt

Low-priced

High holding times

Application area: Packaging, conveyor technology, automation, food technology.

Materials table

| General features | Unit | iglidur® P210 | iglidur® A180 | iglidur® A350 |

|---|---|---|---|---|

| Density | g/cm3 | 1,4 | 1,46 | 1,42 |

| Colour | yellow | white | blue | |

| Max. moisture absorption at 23 °C and 50 %r.h. | Wt.-% | 0,3 | 0,2 | 0,6 |

| Max. water absorption | Wt.-% | 0,5 | 1,3 | 1,9 |

| Mechanical properties | Unit | iglidur® P210 | iglidur® A180 | iglidur® A350 |

|---|---|---|---|---|

| Max. permissible static surface pressure (+20 °C) | MPa | 75 | 28 | 60 |

| Shore D hardness | 75 | 76 | 76 |

| Physical and thermal properties | Unit | iglidur® P210 | iglidur® A180 | iglidur® A350 |

|---|---|---|---|---|

| Upper long-term application temperature | °C | 100 | 90 | 180 |

| Upper short-term application temperature | °C | 160 | 110 | 210 |

| Lower application temperature | °C | -40 | -50 | -100 |

| Electrical properties | Unit | iglidur® P210 | iglidur® A180 | iglidur® A350 |

|---|---|---|---|---|

| Surface resistance | Ω | > 1011 | > 1011 | > 1011 |

Knife edge roller life cycle test on a silver steel shaft 1.2210, 1 MPa; 0.3 m/s

(German)

Dimensions [mm]

| Ordering number | d1 | d2 | b1 | ||

|---|---|---|---|---|---|

| +0,1 | ±0,1 | -0,3 | |||

P210RLM-0309-50 P210RLM-0309-50 |

3.1 | 9 | 50 | Upon request |  |

A180RLM-0309-50 A180RLM-0309-50 |

3.1 | 9 | 50 | Upon request |  |

A350RLM-0309-50 A350RLM-0309-50 |

3.1 | 9 | 50 | Upon request |  |

A350RLM-0614-70 A350RLM-0614-70 |

6.1 | 14 | 70 | Upon request |  |

A350RLM-0818-70 A350RLM-0818-70 |

8.1 | 18 | 70 | Upon request |  |

P210RLM-0409-50 P210RLM-0409-50 |

4.1 | 9 | 50 | Upon request |  |

A180RLM-0409-50 A180RLM-0409-50 |

4.1 | 9 | 50 | Upon request |  |

P210RLM-0511-70 P210RLM-0511-70 |

5.1 | 11 | 70 | Upon request |  |

A180RLM-0511-70 A180RLM-0511-70 |

5.1 | 11 | 70 | Upon request |  |

P210RLM-0514-70 P210RLM-0514-70 |

5.1 | 14 | 70 | Upon request |  |

A180RLM-0514-70 A180RLM-0514-70 |

5.1 | 14 | 70 | Upon request |  |

P210RLM-0612-70 P210RLM-0612-70 |

6.1 | 12 | 70 | Upon request |  |

A180RLM-0612-70 A180RLM-0612-70 |

6.1 | 12 | 70 | Upon request |  |

P210RLM-0614-70 P210RLM-0614-70 |

6.1 | 14 | 70 | Upon request |  |

A180RLM-0614-70 A180RLM-0614-70 |

6.1 | 14 | 70 | Upon request |  |

P210RLM-0812-70 P210RLM-0812-70 |

8.1 | 12 | 70 | Upon request |  |

A180RLM-0812-70 A180RLM-0812-70 |

8.1 | 12 | 70 | Upon request |  |

P210RLM-0814-70 P210RLM-0814-70 |

8.1 | 14 | 70 | Upon request |  |

A180RLM-0814-70 A180RLM-0814-70 |

8.1 | 14 | 70 | Upon request |  |

P210RLM-0816-77 P210RLM-0816-77 |

8.1 | 16 | 77 | Upon request |  |

P210RLM-0818-70 P210RLM-0818-70 |

8.1 | 18 | 70 | Upon request |  |

A180RLM-0818-70 A180RLM-0818-70 |

8.1 | 18 | 70 | Upon request |  |

P210RLM-1020-70 P210RLM-1020-70 |

10.1 | 20 | 70 | Upon request |  |

A180RLM-1020-70 A180RLM-1020-70 |

10.1 | 20 | 70 | Upon request |  |

| More about selected part: | |||||

3D-CAD Sample request

Sample request PDF

PDF Quote request

Quote request Price list

Price list myCatalog

myCatalog

|

|||||

Available ex stock

More information:

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!