Dimensional stability when wet

Polymer plain bearings in mountain bikes with a spring-mounted rear wheelContrail MGN from Bergamont is currently the top model among full-suspension mountain bikes. The Hamburg-based bicycle brand has developed this bike with innovative technology, such as butted frame tubes with various wall thicknesses as well as carbon frame components. Light polymer plain bearings are used to handle severe stresses at the dropouts of the rear suspension.

Anyone who rides mountain bikes for fun and professionally will find a "Fully" [full suspension bike] to be the best for this leisure sport – a bike with a spring-mounted rear wheel. It is a far more comfortable ride and ultimately faster, because the rider has to respond less to uneven ground. The adjustment of the suspension must be good and tight in order to provide the comfort desired. Firstly, it absorbs quick jolts well, thus not endangering the stability of the rear suspension. The whole thing must also be "drive-neutral" and the motions of the suspension must not be transferred to the pedals.

For insiders, the ConTrail MGN from Bergamont of Hamburg is a dream of a trail bike or mountain bike.

Bicycle designers and experts know that there are several types of rear suspension. In addition to "single linkages" and "multi-linkages", there is the so-called "supported single linkage" with a bell crank on the frame.

This principle was chosen for the frame development of the

Contrail MGN model, by graduate engineer Thomas Marquardt, designer at Bergamont and also product manager

for high-quality wheels for sporting goods. These "Top Fullys"

in the trail bike category are for athletes who both win marathons and also want to enjoy cycling for fun.

The definition of the pivot points plays a very important role in designing a rear suspension. Thomas Marquardt says "We have precise ideas about how a bicycle should be ridden and we conduct extensive tests during the development phase. "This is true not only for the placement of the pivot points and consequently for the kinematics, but also for the choice of bearing points. Bergamont originally used ball bearings for all the bearing points of its "Fullys". The Contrail MGN is the first time they have deviated from this principle. "At the two front pivot points", says Marquardt, "at the connection between the swingarm and the frame, we used deep groove ball bearings, because the bearings here have to execute a relatively large swivel movement. At the rear joint, on the rear axle, we are taking a new approach this time and using a plain bearing". “

There are good reasons for the designer to ensure these features, the most important being lateral stiffness. A plain bearing offers a much larger contact area than a roller bearing. "Even with very severe stresses and large lateral forces, nothing wobbles", Marquardt explains.

The plain bearings will also do very well with the high pressure loading at this bearing point.

"The pressure is also very well distributed over the larger area. "Bergamont's experiments with plain bearings on the suspension joint were supported by bearings specialist igus®. The job also required selecting the optimal bearing material. René Achnitz, Global Product Manager of “iglidur®” plain bearings says: "In the initial experiments, we used the “iglidur® G” an all-round material, but then we established that "iglidur® J" works better". “

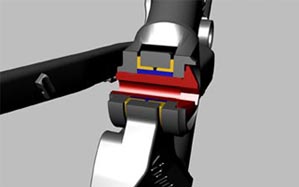

At the rear hinge on the rear axle, the designers took a new approach and used a plain bearing. The "iglidur® polymer bearings", offer a much larger contact area than roller bearings. No wobbling, even under very severe stresses and large lateral forces.

It was obvious why the first experiments were done with "iglidur® G". This universal material offers the broadest range of applications for particularly economical bearings. But “iglidur® J” provides greater dimensional stability when wet, and this parameter

also had to be considered in the bike design.

Naturally the wheels often run through streams and puddles, and they are often cleaned after use with a garden hose or even a pressure washer. Thomas Marquardt explains "These stresses are no problem for polymer plain bearings". “

Careful design: the plain bearing is gently forced into the swingarm. A bearing is inserted into a metal sleeve, which forms the end stop for tightening the screws.

The self-lubricating “iglidur®” polymer plain bearings can expect a long and reliable service life. However, the specialized dealers' ‘marketing’ had to convince people first. Thomas Marquardt says "We used plain bearings a few years before, but they were made of other materials, and were too small. So now we had to provide information and training. "The dealers were perfectly happy with the present solution because the feedback from bike owners turned out to be 100% positive. The torsional stiffness of the wheel is very good and the suspension responds very quickly, Marquardt reports.

"iglidur® J", wear-resistant bearings made from this material have a particularly high dimensional stability when wet – a crucial parameter, if the bike goes through streams and puddles.

The very careful design of the bearing point certainly contributes to this. In the bike production, the plain bearings are gently forced into the swingarm. A bearing is inserted into a metal sleeve, which forms the end stop for tightening the screws. So the bearings keep rotating, even after assembly by the bicycle owner.

The innovative use of plain bearings is one of many details by which Bergamont demonstrates its high-tech claim for mountain bikes and trail bikes. Other design features include butted tubes with varying wall thicknesses, which contribute to the light weight of only 10.8 kg. The fork is fitted with a carbon crown; the dropouts are 3D forged.

The lines of the Contrail MGN are just as satisfying as the performance characteristics, because Bergamont has not only carried out its own frame development for more than ten years, using the most modern CAD tools, but it also uses an industrial designer who conveys the stylistic elements of the brand. Bergamont has defined not just sportiness but also stability as an important stylistic element. The polymer plain bearings from igus contribute to this.

For example, the bike of Olympics winner Sabine Spitz (gold medal in Beijing 2008), already had iglidur® plain bearings in a sensitive suspension fork. The polymer components stood up to the constant impacts, edge loads, and dirt on the difficult and spectacular Olympic course at the Chinese Laoshan Velodrome. Also at the 2004 Olympics in Athens, “iglidur®” was on the winners' podium too, light, wear-resistant iglidur bearings were built into the guide rollers of the derailleurs. The bikers at the end won the gold, silver, and bronze medals.

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!