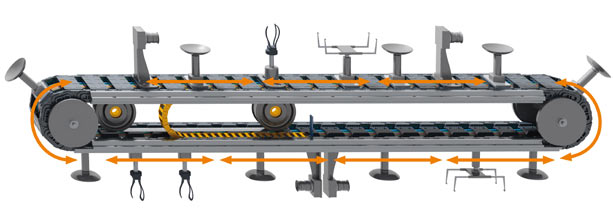

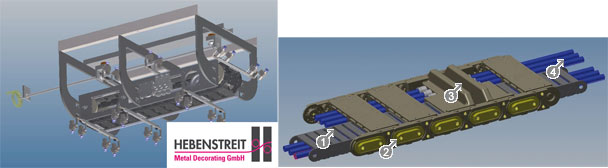

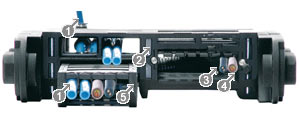

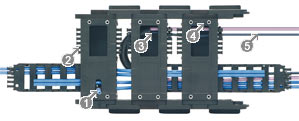

Intelligent conveyor chain with integrated power & data supply

Give each conveyor link a separate function.

Equip it with grippers, suction cups, tools, sensors, cameras, and, and, and…

Reduce pick & place times drastically: Up to 30% faster

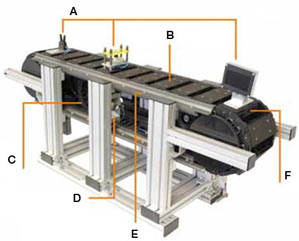

Technical Data (preliminary).

Travel: up to 30 m.

Continious speed: 2-3 m/s.

Installation: horizontal, vertical and side mounted 90°.

Max. load per conveyor chain link: approx. 5,0 k.