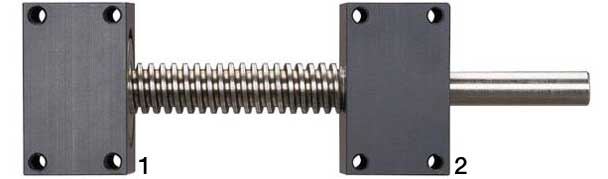

Lead screw bearing with fixed and floating bearing blocks, right-handed

1 = Fixed bearing side FL

2 = Floating bearing side LL

Anodized aluminum bearing blocks. Design your own linear table.

Flexible mounting of the leadscrew

Leadscrew diameter: 10, 18 and 24 mm

Combination fixed/floating bearing

Lubricant-free through built-in plastic bearing

Industries:General mechanical engineering

|

Part No.: |

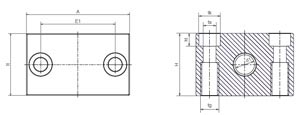

| Part. No. | A | H | E1 | E2 | E3 | E4 | lt | tk | ts | tg | kt | d1* | d2 | d3 | ha | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | |||

SLS-10x2-LH SLS-10x2-LH |

50 | 32 | 36 | - | - | - | 30 | 11 | 6.6 | M8 | 6.5 | 10 | - | - | 16 | Upon request |  |

SLS-10x3-LH SLS-10x3-LH |

50 | 32 | 36 | - | - | - | 30 | 11 | 6.6 | M8 | 6.5 | 10 | - | - | 16 | Upon request |  |

SLS-18x4-LH SLS-18x4-LH |

72 | 46 | 54 | - | - | - | 36 | 15 | 9 | M10 | 8.6 | 18 | - | - | 23 | Upon request |  |

SLS-24x5-LH SLS-24x5-LH |

94 | 64 | 70 | - | - | - | 50 | 20 | 13.5 | M16 | 13 | 24 | - | - | 32 | Upon request |  |

SLS-10x2-LL SLS-10x2-LL |

50 | 32 | 36 | 27 | 6,5 | 20 | 30 | 11 | 6.6 | M8 | 6.5 | 10 | 0 | - | 16 | Upon request |  |

SLS-10x2-FL SLS-10x2-FL |

50 | 32 | 36 | 0 | 0 | 0 | 30 | 11 | 6.6 | M8 | 6.5 | 10 | 26 | 5 | 16 | Upon request |  |

SLS-10x3-LL SLS-10x3-LL |

50 | 32 | 36 | 27 | 6,5 | 20 | 30 | 11 | 6.6 | M8 | 6.5 | 10 | - | - | 16 | Upon request |  |

SLS-10x3-FL SLS-10x3-FL |

50 | 32 | 36 | - | - | - | 30 | 11 | 6.6 | M8 | 6.5 | 10 | - | - | 16 | Upon request |  |

SLS-10x12-LL SLS-10x12-LL |

50 | 32 | 36 | 27 | 6,5 | 20 | 30 | 11 | 6.6 | M8 | 6.5 | 10 | - | - | 16 | Upon request |  |

SLS-10x12-FL SLS-10x12-FL |

50 | 32 | 36 | - | - | - | 30 | 11 | 6.6 | M8 | 6.5 | 10 | - | - | 16 | Upon request |  |

SLS-10x50-LL SLS-10x50-LL |

50 | 32 | 36 | 27 | 6,5 | 20 | 30 | 11 | 6.6 | M8 | 6.5 | 10 | - | - | 16 | Upon request |  |

SLS-10x50-FL SLS-10x50-FL |

50 | 32 | 36 | - | - | - | 30 | 11 | 6.6 | M8 | 6.5 | 10 | - | - | 16 | Upon request |  |

SLS-18x4-LL SLS-18x4-LL |

72 | 46 | 54 | 27 | 13,5 | 20 | 36 | 15 | 9 | M10 | 8.6 | 12 | 0 | - | 23 | Upon request |  |

SLS-18x4-FL SLS-18x4-FL |

72 | 46 | 54 | 0 | - | 0 | 36 | 15 | 9 | M10 | 8.6 | 18 | 42 | 6,6 | 23 | Upon request |  |

SLS-18x8P4-LL SLS-18x8P4-LL |

72 | 46 | 54 | 27 | 13,5 | 20 | 36 | 15 | 9 | M10 | 8.6 | 12 | - | - | 23 | Upon request |  |

SLS-18x8P4-FL SLS-18x8P4-FL |

72 | 46 | 54 | - | - | - | 36 | 15 | 9 | M10 | 8.6 | 18 | - | - | 23 | Upon request |  |

SLS-18x24-LL SLS-18x24-LL |

72 | 46 | 54 | 27 | 13,5 | 20 | 36 | 15 | 9 | M10 | 8.6 | 12 | - | - | 23 | Upon request |  |

SLS-18x24-FL SLS-18x24-FL |

72 | 46 | 54 | - | - | - | 36 | 15 | 9 | M10 | 8.6 | 18 | - | - | 23 | Upon request |  |

SLS-18x100-LL SLS-18x100-LL |

72 | 46 | 54 | 27 | 13,5 | 20 | 36 | 15 | 9 | M10 | 8.6 | 12 | - | - | 23 | Upon request |  |

SLS-18x100-FL SLS-18x100-FL |

72 | 46 | 54 | - | - | - | 36 | 15 | 9 | M10 | 8.6 | 18 | - | - | 23 | Upon request |  |

SLS-24x5-LL SLS-24x5-LL |

94 | 64 | 70 | 27 | 22,5 | 20 | 50 | 20 | 13.5 | M16 | 13 | 14 | 0 | - | 32 | Upon request |  |

SLS-24x5-FL SLS-24x5-FL |

94 | 64 | 70 | 0 | - | 0 | 50 | 20 | 13.5 | M16 | 13 | 24 | 52 | 8 | 32 | Upon request |  |

| More about selected part: | |||||||||||||||||

3D-CAD Sample request

Sample request PDF

PDF Quote request

Quote request Price list

Price list myCatalog

myCatalog

|

|||||||||||||||||

| Part. No. | Weight | Max. stat. load capacity |

|---|---|---|

| [g] | axial [N] | |

SLS-10x2-LH SLS-10x2-LH |

88 | 700 |

SLS-10x3-LH SLS-10x3-LH |

88 | 700 |

SLS-18x4-LH SLS-18x4-LH |

205 | 1.6 |

SLS-24x5-LH SLS-24x5-LH |

525 | 2.5 |

SLS-10x2-LL SLS-10x2-LL |

115 | 0 |

SLS-10x2-FL SLS-10x2-FL |

88 | 700 |

SLS-10x3-LL SLS-10x3-LL |

115 | - |

SLS-10x3-FL SLS-10x3-FL |

88 | 700 |

SLS-10x12-LL SLS-10x12-LL |

115 | - |

SLS-10x12-FL SLS-10x12-FL |

88 | 700 |

SLS-10x50-LL SLS-10x50-LL |

115 | - |

SLS-10x50-FL SLS-10x50-FL |

88 | 700 |

SLS-18x4-LL SLS-18x4-LL |

295 | 0 |

SLS-18x4-FL SLS-18x4-FL |

205 | 1600 |

SLS-18x8P4-LL SLS-18x8P4-LL |

295 | - |

SLS-18x8P4-FL SLS-18x8P4-FL |

205 | 1.6 |

SLS-18x24-LL SLS-18x24-LL |

295 | - |

SLS-18x24-FL SLS-18x24-FL |

205 | 1600 |

SLS-18x100-LL SLS-18x100-LL |

295 | - |

SLS-18x100-FL SLS-18x100-FL |

205 | 1600 |

SLS-24x5-LL SLS-24x5-LL |

725 | 0 |

SLS-24x5-FL SLS-24x5-FL |

525 | 2500 |

| More about selected part: | ||

3D-CAD Sample request

Sample request PDF

PDF Quote request

Quote request Price list

Price list myCatalog

myCatalog

|

||

Useful extension to the drylin® construction kit

The drylin® screw drives modular kit is now also supported by the new screw bearing block with already pressed-in ball bearings. It provides for flexible positioning of lead screws in many applications. The installation height of the system matches the components of the drylin® R product range - linear bearings and housings. Bores in the face provide for simple assembly of igus® motors and motor installation kits. The use of ball bearings also allows high RPMs to be transferred at the best possible efficiencies.

Lubricant- and maintenance-free

Quick connection

Transmission of high rotation speed

Low friction

Accurate and clearance-free

Application areas:Ball bearing linear drives, e.g. SLW-BB, lift tables and adjustments for general mechanical engineering.

|

Part No.: |

| Ordering number | Weight | Max. stat. F axial |

A | H | E1 | E5 | E6 | lt | tk | ts | tg | kt | d1 | ha | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [g] | [N] | |||||||||||||||

SLS-10x2-BB SLS-10x2-BB |

110 | 350 | 50 | 32 | 36 | 40 | 20 | 30 | 11 | 6.6 | M8 | 6.5 | 10 | 16 | Upon request |  |

SLS-10x12-BB SLS-10x12-BB |

- | 350 | 50 | 32 | 36 | 40 | 20 | 30 | 11 | 6.6 | M8 | 6.5 | 10 | 16 | Upon request |  |

SLS-10x50-BB SLS-10x50-BB |

- | 350 | 50 | 32 | 36 | 40 | 20 | 30 | 11 | 6.6 | M8 | 6.5 | 10 | 16 | Upon request |  |

SLS-18x4-BB SLS-18x4-BB |

265 | 1000 | 72 | 46 | 54 | 48 | 36 | 36 | 15 | 9 | M10 | 8.6 | 18 | 23 | Upon request |  |

SLS-18x8P4-BB SLS-18x8P4-BB |

- | 1000 | 72 | 46 | 54 | 48 | 36 | 36 | 15 | 9 | M10 | 8.6 | 18 | 23 | Upon request |  |

SLS-18x24-BB SLS-18x24-BB |

- | 1000 | 72 | 46 | 54 | 48 | 36 | 36 | 15 | 9 | M10 | 8.6 | 18 | 23 | Upon request |  |

SLS-18x100-BB SLS-18x100-BB |

- | 1000 | 94 | 46 | 70 | 48 | 36 | 36 | 15 | 9 | M10 | 8.6 | 24 | 23 | Upon request |  |

SLS-24x5-BB SLS-24x5-BB |

650 | 1500 | 94 | 64 | 70 | 48 | 36 | 50 | 20 | 13.5 | M12 | 13 | 24 | 32 | Upon request |  |

| More about selected part: | ||||||||||||||||

3D-CAD Sample request

Sample request PDF

PDF Quote request

Quote request Price list

Price list myCatalog

myCatalog

|

||||||||||||||||

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!