Shock absorber

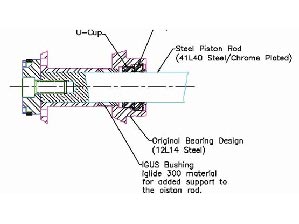

The level of the lateral load, which the shock absorber is able to withstand, had to be increased. But there was no direct support for the piston rod. It could only cope with 30% of the maximum energy output. The gap between the bearing and the rod caused the piston rod to wear unevenly on the seals, which resulted in premature failure. A special size bearing was developed so that it fits into the existing bearing without hindering the wall thickness. The iglidur® G bearing provides adequate support for the piston rod, meaning that the joint can handle over 70% of its maximum energy output.

Go to applied products here

Further interesting applications from extremely diverse areas can be found here.

Go to manus® contest