From Airbus to Boeing

Space-saving energy supply system for safety bars on gate systemsEvery aircraft hangar is equipped with a high-quality door. Whether Airbus or Boeing, private or military aircraft: It is always a customer-specific solution, meticulously planned and executed. As the safety requirements increase constantly in the highly complex facilities, the doors are increasingly equipped with closure-edge safety systems. Special energy supply systems provide for a smooth transmission of information, so that neither people nor machines are injured or damaged in case of an emergency.

Thomas Ruf, head of design at Butzbach GmbH Industrial Doors in Unterroth, states at first, "No door is equal to another." "Always we plan an individual facility for each customer, as the basics of use always differ. " From A like Ankara to Z like Zurich: There is almost no airport and no airline in Europe that doesn't rely on the company's door solutions. "We have developed a special door for the zeppelin hall in Friedrichshafen as well," says the head of design regarding the various assignments.

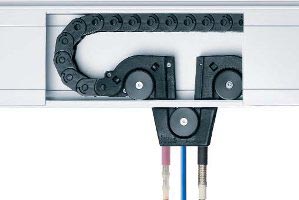

Compactly built: Energy supply system of the safety edge on door systems

The Airbus A380 brought to Butzbach the biggest order till date in the company's history few years ago. We planned and erected a hangar door here 190 m wide and 27 m high for the German base in Hamburg. Even door solutions for military vehicles or freighters with top control surfaces do not pose problems for us. We are flexible and fulfill almost every wish of our customer," says Thomas Ruf, clarifying the corporate philosophy. Even hangar doors with over 300 m width and 30 m height don't constitute any technical challenge. "More than 500 installed special doors make us the market leader in Europe. “

Every door is a special design. According to space needed and requirement profile, the specialist implements individual solutions of all sizes for the industry and aviation. There are sliding doors with individual movable wing doors, telescopic/round-the-corner doors - with or without electric drive. The "Micro FLIZZ®" special energy supply system from igus® GmbH, Cologne, has been proving its worth for about two years particularly in the space-saving, increasingly used telescopic system. It is an E-Chain® solution for horizontal applications, which feeds energy to the moving load via rolling and/or glide carriages. It runs in a compactly built aluminum guide channel that separates the upper and lower runs of the E-Chain® in a weight-saving manner. Friction and wear are at a minimum due to the low force effects. The compact, space-saving system is closed at the top and thus offers protection against dirt and dust.

The function system of the telescopic system has a series of advantages: The first wing door is the driving element. All others are hauled and run over a cable system with varying speeds. All the door elements of a door side reach the stand-by position at the same time (or closing position). The advantages are obvious: The operator needs to operate only an operating knob, so that all wings move. As each individual wing is not separately moved, one needs altogether less drive, less power supply systems and power rails.

The energy supply system "Micro FLIZZ®" from igus® is used among other things in round-the-corner doors. It proves its worth compared to the high-maintenance power rails and insecure contact lines.

"As the concerns for safety of our customers are increasingly become larger, they want every door wing to be provided with a separate closure-edge safety system," narrates Thomas Ruf from his experience. "To enable the flow of information from the individual closure-edge safety systems from wing door to wing door, a continuously secure connection is required. No contact lines. And here the energy supply solution "Micro FLIZZ®" comes into play.

In door systems particularly high masses are moved which have to be safely braked. A wing door can weigh from 500 kg to 60 tons. The energy supply system is attached on the driven wing door. The information of the individual closure-edge safety systems are 'loopedthroughed' from wing door to wing door and connected to the door control. If one closure edge is activated, the control system responds directly, the motor immediately switches off and the entire door comes to a stop. Then it is reversed and goes back about 1 m, so that the obstacle is removed.

As the nominal voltage of the safety system generally amounts to 24 V, power rails and contact lines have a series of disadvantages. As environmental conditions cloud/corrode the sliding contacts or copper tracks, a trouble-free operation is not guaranteed. The rails are mounted outside and are thereby exposed to wind and weather. If it is misty, for instance, an oxide layer forms on the contact. "Nominal voltage of 220 or 230 V is no issue," says the Head of Design. "But at 24 V, the risk of an outage is too high. For this reason we need the cable connection, and that is possible only through the E-Chain®. “

The E-ChainSystem® becomes primarily important in telescopic doors. "In the beginning we used our normal standard power rail for data transmission, but quickly determined that its functioning was limited and it was too susceptible. The initial complaints began to come in after one year at the latest," the head of design looks back. The rail was responsible for the fault. It was not flexible enough in the carriage area. Then there is the extremely narrow space conditions on site, which make the installation and repair considerably difficult.

The igus® "Micro FLIZZ®" system: As soon as the E-Chain® bends in the radius, the side wings turn flat. The chain can leave the slot and freely lay down.

"Our requirements have to do with rugged outdoor use," reports Thomas Ruf. The energy supply system should withstand rain, snow, fog, frost and heat. Although the energy supply system lies under the roof, it is freely accessible from below. Due to the low speed of 0.25 m/s and the comparatively unusual travel frequency, the door specialist could cut back in the bending radii of the used bending-resistant "Chainflex®" cables for the information transmission. "Due to the relatively low mechanical stressing here, we can lay not only more cables in the E-Chain®, but in consultation with igus® technicians, also lower the bending radius from factor 5 to factor 3," explains Thomas Ruf. "And the cables still function smoothly. No failures at all till now. “

Although a classical standard contact line is cheaper in principle, it does not however reach the required level of reliable data transmission. Due to the requirements on site – rugged, extremely slender, small and pure information transmission – the use of "Micro FLIZZ®" pays off, so that the igus® system is basically used in the telescopic doors today.

For door systems that require additional cables for the safety system beside the classical power supply, the E-Chain® with double chain strand was used. A conclusive solution was found with the aid of the igus® sales staff member in charge. "Despite the high filling, we have solved the problem," says Thomas Ruf. "Micro FLIZZ®" was mounted in the counter direction The power supply system runs in one direction, while the control system is covered in the other direction. The separation of the data and power supply systems meets, by the way, also EMC requirements. "Today the customer presses a button on the wall and his door system moves to the required position. “

In "Micro FLIZZ®" from igus®, the upper and lower runs are separated in a weight-saving manner. The system allows speeds up to 6 m/s in continuous operation.

"Especially at the start, we built in consultation with igus," Thomas Ruf reminisces. "Here operational safety was, of course, the main focus. Today we have established a standard that is applicable and will suit only the respective system." The "Micro FLIZZ®" MF08 Series with preassembled "Chainflex®" cables, also from igus, are used in sliding doors. It generally fulfills all requirements and has proved its worth right from the start. "We have left nothing to chance in the planning and offer an economical solution to our customers, which meets the highest safety standards," concludes the head of design.