“We are opening up new markets”

Energy supply systems and cables for the highest demands in linear drive technologyDirect drive technology is gaining an increasing foothold in automation. Linear motor axes for high-end positioning are very much establishing themselves. This highly complex technology requires extensive technical advise ahead of every application and correspondingly robust components when being implemented. Energy supply systems and cables, for example, must guarantee a long service life despite extreme accelerations. It is possible to draw a positive balance after three years of collaboration between two companies.

Spindle and toothed belt drives are still among the most frequently used electromechanical drive elements in automation. But a change in technology is evident in many fields: for even more accurate and faster positioning tasks in the widest sense of handling technology, linear motor axles are being used more frequently and increasingly represent a technical alternative. Growing market share is forecast.

“The future lies in system technology,” says graduate physicist, Dr. Volker Hamann, Manager of Direct Drives & Systems at HIWIN GmbH in Offenburg, confidently. The Taiwanese manufacturer of linear technology decided early on to have a presence in Europe; it has been operating its European subsidiary since 1993. HIWIN is a universal supplier, which supplies standard solutions for the majority of all applications where linear, planar or three-dimensional movements are required. The company produces and sells a whole range of products from profile rails and ball screws through to complete positioning systems with motor axles, linear modules and and position measuring systems for a wide variety of requirements – from the semi-conductor to the automotive industry.

Energy supply with 'Chainflex®' cables for high-end positioning

Whilst HIWIN has around 1200 employees in Taiwan, around 75 are employed in Germany and Japan and around 45 in the USA. “We are very global-minded. The Taiwanese business acumen coupled with the German thoroughness results in an optimum concept,” says Volker Hamann summarizing the product philosophy succinctly. “Our linear drives are tailor made to the application in question; there is no oversizing with us. They are made out of high quality components at a thoroughly affordable price. ”

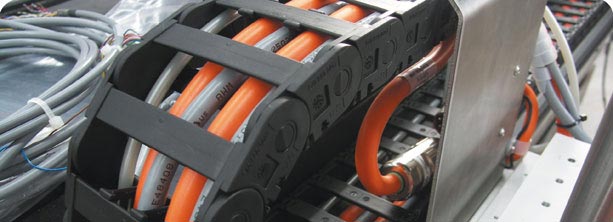

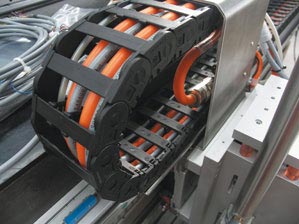

Added to that is their service-friendliness. It revolves around an open concept; all components are accessible, nothing is encapsulated. “The axles are maintenance-friendly and have a modular design,” says Volker Hamann. Both the energy supply systems and the cables come from igus®. Servo cables from the 'Chainflex® CF27' Series and instrumentation system cables from the 'Chainflex® CF211' and 'CF111.D' Series are used. Then there are the two-part energy supply systems 'E2/000, Series 1400' and '2400'.

“Since 2003 we have also been building up system technology in Europe in the form of a technical skills group, which there has been at the parent company in Taiwan since 1997. In the meantime, ten application engineers at our company alone are occupied just with this matter,” says Volker Hamann explaining the background. “Our strategic aim is to gain a stronger foothold in automation in Germany. The linear motor enables higher speeds and accuracies and is now having an effect in an increasing number of applications. But our customers making the change to direct drive technology need a competent partner who will accompany them during this process. And we want to occupy this niche in automation with our products. “

HIWIN is focussing on customized solutions. All the applications relating to high-end positioning represent new territory as a rule, so the demands on the component suppliers are correspondingly high. Says Volker Hamann: “The profile rails and motors are our core competence, but the remaining components such as the energy supply systems and the cables must be of equally high quality. And because the applications are used under vastly different conditions – from cleanrooms to dirty environments – we cannot install any solution off the peg. What is more, we do not have the inclination and above all the time to keep on changing suppliers. When looking for a competent partner in the field of moving energy supply and dynamically moving cables, it was therefore important for us to find a wide product range and a good image in the market. “

Energy supply systems and 'Chainflex®' cables guarantee a long service life despite the highest accelerations

For around three years the supplier of linear drives has been working together with the specialist for cables and energy supply systems, igus®. “We also appreciate the company due to its flexibility. We are still in the start phase with system technology and thus need a lot of advice and support with our customized projects,” remarks Volker Hamann. “Our expertise is concentrated on the positioning systems and not on the layout of cables and energy supply systems, which have to be adapted to the respective requirements on site. “

Europe is a target market for HIWIN. The focus in Taiwan is on accuracy, in Europe it is on dynamics. Volker Hamann gives the following explanation about this: “Our parent company in Taiwan became big with high precision air cushion tables for the semiconductor industry. Positioning accuracies in the tenth of a µ range are now required here, whereas in Europe there is a demand for positioning solutions in the tenth of a mm range when moving from one place to another. “

Linear motors are today used in pipe cutting machines, for example. A customer from the automotive industry wanted to cut stainless steel pipes with holes. For optical reasons, the cut was not supposed to be done through a hole but instead be done between two holes, which happened with the help of a camera. The pipe is positioned above a camera. The target position is transmitted in the 50 microsecond range. The axle is positioned to 2 µ in 3.5 m/s; the acceleration is in the 2 g range. The number of cycles reached 200,000 pipes over the weekend. Accuracy, dynamics and the high number of cycles constituted the design challenge. The whole unit with the energy supply system and the cables runs practically without wear – despite the high incidence of chipping.

igus® cables for the HIWIN torque motor

Other uses are in wafer quality control. High precision cross tables with air bearings are used here as the basis for a surface check that will find even the smallest defect. This involves an air cushion table, which moves 500 x 500 mm to an accuracy of half a µ. “This is a high-end solution, which is set up at the customer in the clean room. Our service engineer then installs the solution on site,” explains Volker Hamann.

Linear axes are also used with absolute position measurement in a horizontal high speed heating element welding machine for welding plastics. The tubes are pressed onto the heating plates. If too much is used, the bead gets too strong; if too little pressure is used, there is not enough purchase. That means that pressure must be applied in a controlled manner, without 'stringing'. The mixture of dynamics and force control is another argument in favor of linear motors. “This has led to plastic welding machines that now process plastics, which did not used to work like that just a few years ago,” says Volker Hamann.

Accelerations up to 10 g, speeds up to 5 m/s, rated voltage 600 V, small installation space and long service life plus UL approval are the basic requirements of the cables. Servo cables from the 'Chainflex®' Series 'CF27' are used as drive cables for the motor. Due to its compact structure, with gusset-filling pressure extruded inner jacket and PUR outer jacket with high abrasion resistance, the 'CF27' Series is suitable for heavy-duty use. It can be used to achieve an acceleration of up to 100 g without any problem. In order to be able to ensure the highest possible EMC safety, a special braided shield with optimized braid angle and 90 % optical cover is used, which leads to no shield wire breaks even with high stroke numbers in linear drives.

Added to this, the 'CF211' measuring system cables for heavy duty and 'CF111.D' for particularly oily wet areas are used. “The latter are used first and foremost for rotary tables in order to ensure the resistance of the outer jacket due to the oily environment,” Volker Hamann points out.

Both the servo and measuring system cables are supplied with connectors on both sides. “After initial problems with the IP67 leak tightness of the assembled connectors, we now test them for leak tightness again beforehand,” explains Rainer Rössel, responsible at igus® for all questions about 'Chainflex®' cables. “We can only improve product quality by reacting thoroughly to complaints,” he says clarifying the igus® strategy.

Jochen Becker (igus® GmbH), Dr. Volker Hamann (HIWIN), Rainer Rössel (igus® GmbH) have been working together with great success for about three years.

“We now see ourselves as a system supplier,” says Rainer Rössel to make the igus® company philosophy clear. “From our portfolio of over 750 cables and over 80,000 other products from stock, we supply tailor-made solutions for every customer application – without minimum order quantities or surcharges. Around 1500 deliveries leave our doors every day, with no two being the same. There is almost no such thing as standard any more!”

Volker Hamann adds: “We are opening up new markets with linear technology. We expect our partner to react constructively and flexibly to our questions and offer solutions that work. A number of our customers assemble their products themselves. We now specify igus® cables because we recognise their reliability under the highest demands. In the early days we used to have problems with many other cables,” says Volker Hamann summing up the good co-operation between the two companies to finish with.