Used in Shanghai

igus® control cable: highly bending resistant thanks to specially alloyed conductorThe Chainflex® CF98 control cable developed by igus®, presented to the trade public last year, is already providing significant savings with E-Chain® applications in tight installation spaces. Shanghai Novel Color Picture Tube Co. Ltd., a Chinese company owned by the electronics giant Novel, has been using the cable for tight bending radii since October 2004 at its plant in the south-west of Shanghai City with success. The igus® cable, whose conductor was produced using a special alloy, stays securely in the E-Chain® even with a bending radius of 4xd and smaller (d = cable diameter) at over 30 million double strokes. Chainflex® CF98, specially developed for the critical area of very small cross-sections combined with particularly tight radii, made of a highly abrasion resistant, gusset-filling pressure extruded TPE outer jacket, is oil-resistant, resistant to UV radiation and is PVC and halogen-free.

Yang Rong, responsible for “Slim Production” at the Novel Color Picture plant in Shanghai: “Space here is particularly tight. That is why we needed a high bending strength cable. “

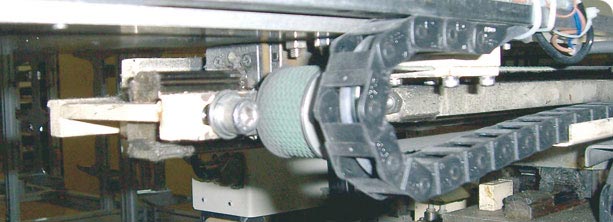

The new automated stacking unit for phosphorous screens in the Shanghai Novel plant used to break down on numerous occasions. Maintenance engineers then discovered that the control cable (cross-section 3x0.25mm2) used next to two air pipes was faulty. Yang Rong, responsible at the plant for “Slim Production”: “The distance here amounts only to a meter with 300,000 double strokes per month. The space for the unit is conceivably small. The bending radius of the E-Chain® is correspondingly tight at just 18 mm. ” The control cable with a copper conductor was not able to withstand the mechanical stresses in the E-Chain® in such tight conditions. After operating for just one week, the unit had to be stopped for over 20 minutes several times to replace the cable. Yang Rong: “We have eight stacking tables of the same type in our unit. The same problem occurred everywhere and there was interference in the screen feed. ” He puts the costs of lost profits as a result of machine downtimes at 70,000 RMB (around 6,500 EUR) – “that comes to, even at a conservative calculation, 0.8 million RMB a year (around 75,000 EUR),” says Rong.

Reliable in the tightest space

Since the installation of Chainflex® CF98.02.03 (diameter: 5 mm), approved and tested for a bending radius of only 4xd, there have been no more operating failures in the Shanghai plant. The particular design difference to conventional cables lies in the conductor material used. Copper is normally used in the widest range of conductor designs. The alloyed conductor in the igus® cable in contrast is softer in its molecular structure, so unlike coppers conductors does not become brittle and fragile so quickly in tight, harsh environments. The new alloy therefore achieves a higher service life. During trials in the igus® laboratory, no damage to the conductors was found even with bending radii of 3.2xd after over 30 million double strokes. Chainflex® CF98 is – in over 25 igus® branches worldwide – available from stock, without costs for cutting to size or surcharges for small quantities.