As iglidur® plain bearings have a long service life, and in addition need not be lubricated and costs only a fraction compared to conventional bearings, 90% of the costs could be saved.

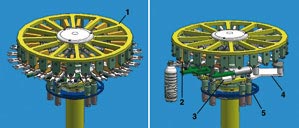

In addition to the technical advantages, the beverages producer Krones could reduce the costs in pull-back stars with the iglidur® X and J plain bearings.

Development engineer Tino Sickert remarkably clarifies the reduction of costs with a concrete example: "In sliding star, which has a similar nature, conventional linear guides were used. Due to the short cleaning cycles and the aggressive cleaners, the lubricants were gradually cleaned off and the guides increasingly underwent dry runs. We had to replace all of them every three weeks, and that too at a unit price of €50 and materials cost of €1200 per replacement. The purchase price of a plain bearing bushing amounts to only a fraction - here, we already save 90 percent! Since we replaced the sliding and pull-back stars, which was in October 2006, we also haven't had any failures or production stops due to the pull-back star. In addition, the routine replacement of the plain bearing hasn't become a necessity till today. “