Fish processing on the high seas.

Plastic plain bearing for roller chains in head-processing and slaughter machineFreshly caught fish are nowadays increasingly processed at once on fishing trawlers. Sophisticated fish-head processing and slaughter machines from Baader, Luebeck, processes 32 fish per minute (max. 90 cm long weighing 7 kg).

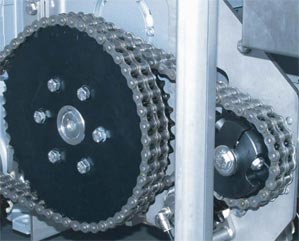

The machine components are therefore exposed to an aggressive mixture of seawater and blood. Here the lubricant-free "iglidur®" plastic plain bearing from igus® GmbH, Cologne, proves itself. The maintenance-free polymer bearings are integrated in rust-free roller chains, which is used for driving the main and ancillary units.

Below the deck 1.5 tons of heavy machinery processes fish in two shifts. The whole thing happens in sea condition, with multidirectional accelerations up to three times that of the acceleration of gravity which act directly on the machines and their components.

As operation is at sea and maintenance on the chain drive is not allowed by the limited personnel there, machine builder Baader relies on rust-proof "12 B-2" roller chains from Wippermann Engineering, Hagen. Previously used conventional roller chains were already worn out after 400 to 450 hours and had to be replaced.

Due to the new solution with Wippermann's "marathon chain", the operating time in contrast could be increased in the meantime to over 3,000 operating hours without the chains being relubricated or retightened.

Fishing trawler with head-processing and slaughter machines below deck.

The enormous increase in service life - without maintenance - for the roller chain is due to its special joint structure. A high-performance polymer bearing from igus was integrated in a stainless steel carrier bushing, "whereby the Tribology of the chain joint was significantly enhanced". The plastic plain bearings distinguish themselves by an extremely high wear resistance, low coefficient of friction, high compressive strength as well as chemical resistance. “ Besides, it is maintenance-free and insensitive to dirt, explains Dr. Gödecke of Wippermann Engineering.

Design and material selection of the polymer plain bearings used by Wippermann have been undertaken in collaboration with igus. Tests at Wippermann confirmed the choice before it was mass produced. The collaboration has led in the past as well to several custom-made bearing solutions for Wippermann chains. Because every chain application poses other demands on the concerned components.

Rust-free roller chain

Plain bearings in roller chains

You will reduce the noise emitted by your roller chain with igus® tribologically optimised iglidur® polymer plain bearings… free of lubricants.