Absolute freedom from lubricants

Prestressed trapezoidal nut, preload force: 50 N

Manually and continuously adjustable radial clearance

Low weight due to aluminium and plastics

Tapered off spindle ends enable operation by hand wheel or motor

Temperature-resistant up to +80 °C

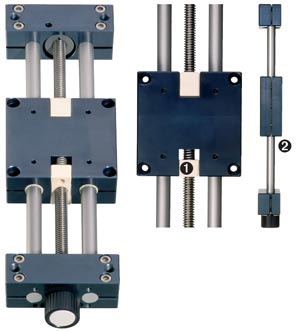

1 - Trapezoidal leadscrew nut with spring preload

2 - Radial clearance adjustable on both sides

SHT-12-AWM-PL

SHT-12-AWM-PL

SHT-12-EWM-PL

SHT-12-EWM-PL