1. Roughly perforated hole/drawn flange

Draws precision from the crude

iglidur®: specialty: Draws precision from the crude

Low clearance iglidur® plain bearing through re-calibration during E-coatingOften low-cost perforated housings and simple cold extruded parts with rough tolerances as pins are used in seat and convertible top systems. However, a bearing with the lowest possible clearance should be achieved to absolutely prevent noise ...

Here is our approach to the solution

For calibration iglidur® plain bearings use the high temperatures generated during drying after the E-coating.

2. Install iglidur® plain bearing with slide fit

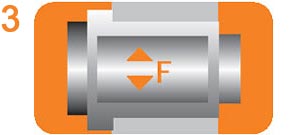

3. Install rivet/pin with cover

4. E-coating (cathodic dip coating)

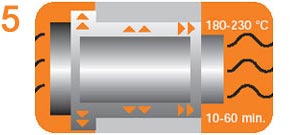

5. "Automatic" recalibration during drying (max.

60 min. at up to 220°C)

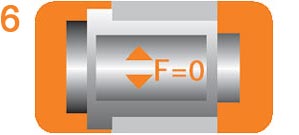

6. Result: Low-clearance bearing in spite of "inaccurate"

hole/pin

Your contact

Markus Feth +49 2203 9649 251 Your requirements?

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!