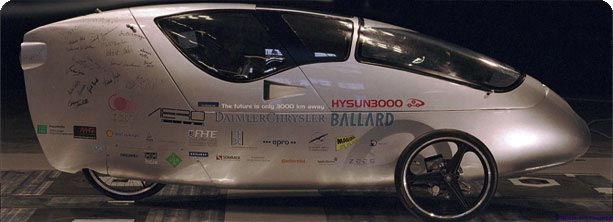

Egg on four wheels

How rod end bearings and polymer bearings make a hydrogen-powered vehicle mobileThe hydrogen-powered "Hysun3000" has successfully completed a 3000 km-long European tour in September 2004. The vehicle required only 3.3 kg of hydrogen to cover the stretch between Berlin and Barcelona, which corresponds to an energy consumption of 12 liters of gas and thus a consumption of 0.4 liters per 100 km. Prerequisite for the world record-breaking project was thereby to save as much weight as possible and at the same time to guarantee the reliability of the system. Crucial engineering design detail: The igus® rod end bearings with male thread and polymer bearings recommend themselves by their low mass and ideal mechanical properties.

The design objective of the record-breaking vehicle "Hysun3000" was to save as much weight as possible and to make the system more reliable at the same time. The entire steering of the vehicle is implemented with steering linkage and spherical bearings. Two steering arms control the wheels. The steering linkage in turn is linked with 14 spherical bearings. This means a weight of around 2.8 kg with conventional spherical bearings. The second problem constituted the tension pulley. An HTD belt connects the rear wheel and the engines with one another. The belt is tightened by means of a tension pulley. The tension pulley should be insensitive to dirt and installed low. Regarding the spherical bearings, a reasonable alternative is found in the igus® type series igubal®. The rod end bearings with male thread possesses a high stiffening. The maintenance-free dry operation and the very low weight add up. Thus the steering is lighter by over 1.5 kg, which corresponds to an extended range of around 100 km.

Tension pulley in the "Hysun3000"

That the fast rotary motions of the mounted shaft take place directly in the bearing ball made of iglidur® W300 counts as an important advantage of the bearing element. The plastic/steel bearings enable high speeds in the dry operation as well. Considering the radial loads, the maximum surface speeds attain up to 0.5 m/s rotating. The angular movements of the spherical bearing in contrast take place on the spheroidal outer diameter of the bearing ball. The maintenance-free bearing elements also permit linear movements of the shaft.

Steering of the vehicle with steering linkage and spherical bearings

The products of the iglidur® W300 type series could help in case of problem in the "tension pulley". The plastic bearings distinguish themselves generally by low thermal relaxation, high compressive strength and dimensional accuracy, as well as heat conduction. Moreover they are maintenance-free, possess a very low creeping tendency and a high mechanical dampening, and are insensitive to dirt. The representatives of the iglidur® W300 family stand for particularly high holding times, low coefficients of friction and extremely high abrasion resistance.