Sought by Mr. Clean

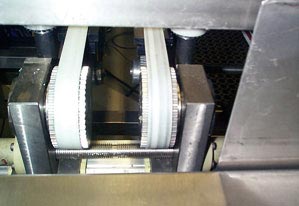

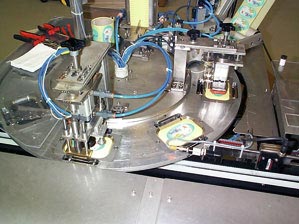

The lubricant-free bearing system is highly recommended for the food and hygiene industryThe packaging machine for hygiene cloths from Stötzer-Maschinenbau serves to provide packaged hygiene cloths with a polyethylene fastening strap. The feeding of the packages takes place over an adjustable toothed belt conveyor at a clock cycle of 1.5 s. This traverses under a clocked rotary indexing table with the stations "lid magazine and sorting", "glue application" and "lid press on".

The lubricant-free igus® bearings are used, among other things, to eliminate a product contaminated by oil or fat. Besides the glide bushings there are, on the one hand, a flange bearing for drive shafts or feed shafts, and on the other, guide systems for pneumatic cylinder as well as axial and horizontal linear guides. The bearings of the iglidur® W300 family thus perform their services in the packaging machine. They stand especially for high holding times, low coefficients of friction and extremely high abrasion resistance. The coefficients of friction also do not increase with higher surface speeds. Therefore compared to other materials it can achieve slightly higher surface speeds, for instance up to 1.5 m/s rotating and up to 5 m/s linear. Due to the extraordinary wear resistance, the bearing wear remains low also in long-term application with high speeds. This is applicable especially for hardened, not so smooth shafts. Shaft roughnesses of 0.4 to 0.5 μm have stood the test of time.

Parallel format adjustment

iglidur® W300 bearing is used also in the ball of the igubal® flange bearing, beside an igumid® G housing. These light flange bearings serve to mount shaft ends or shaft lead-throughs and thereby guarantee high stiffening and fatigue strength. They compensate misalignment and edge loads. As they are maintenance-free, they can be specially considered for applications in which the installation site is less accessible, in humid or wet environment, or (like in the present case) with special demands on hygiene. The humidity absorption rate in normal climate amounts to 1.3 percent by weight. The saturation limit in water is 6.5 percent. This can be considered especially for applications in the packaging industry.

Rotary indexing table with toothed-belt conveyor passing below for application of the polyethylene lid.

The igus® linear bearings installed in the packaging machine operate with gliding elements in contrast to the common recirculating ball bearing systems. The high-performance polymer iglidur® J is for this purpose recommended for most applications due to its good wear and friction properties. The plastic machine elements guarantee maintenance-free and lubricant-free operation, prove to be insensitive to dust and keep the weight on the balance. They run with very low noise, withstand corrosion, carry high loads with regard to statics and are the least harmed by impacts or vibrations. Designed for the dry operation; fatty and oily bearing points have become a thing of the past. On contrary to the ball guides, the plastic options don't depend on the travel length and pose no conditions on a minimum stroke length. The linear bearings from igus® are classified in two geometrically different main groups - the DryLin® R shaft guides as well as the DryLin® T, N and W profile guide rails.