Polymer plain bearings find their way increasingly into traditional organ building

Every organ is a unique piece"In the meantime, we integrate a suitable polymer plain bearing for every pivoting and oscillating motion, as well as for every friction point," explains Richard Baumgartner, junior partner of Baumgartner Orgelbau, a workshop for historic music instruments.

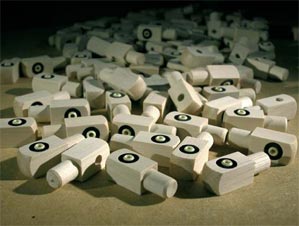

"In our latest project, a gambling table, there would be up to 3,000 bushings and bearings built into it when it is completed. However the technical and economical benefits speak clearly for themselves and satisfy more and more of our customers. "

Used among others are iglidur® J bearings. The material distinguishes itself basically through its low wear against many shaft materials, resistance against chemicals, vibrations dampening and very low absorption of humidity. The low-priced bearing has in addition low coefficients of friction in dry operation and a very good performance with soft shafts.

The absolute freedom from noise in combination with high accuracy has been proven and tested from the start in organ building.

The used bushings should also be extremely wear resistant in association with the shaft materials. V2A steel with a defined surface is used . It should not be too smooth, else it makes a squeaking noise, the so-called stick-slip effect.

A hard and accurate bearing that permits zero backlash and dampens the noise development had to be found. The strong-walled bushings have proved their worth in wood despite the continuously fluctuating environmental conditions in the church. No disturbing rattling noise whatsoever occurs. Moreover the maintenance work can be completely dispensed with.

Bearings are used in the entire organ.

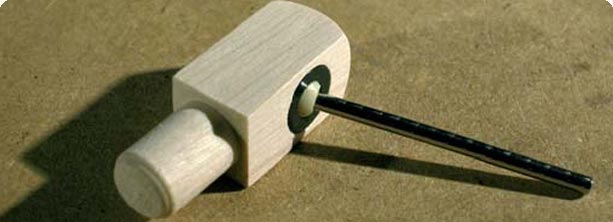

The igubal® type series rod end bearings and clevis joints can be easily used especially in, among others, the stop-action mechanism. It is, among other things, absolutely lubricant-free. The polymer bearings are installed dry and need not be - in contrast to cloth bearings - impregnated with graphite suspension or oily materials.

igubal® is a system of self-aligning bearing elements completely made of plastic. The type series consists of rode end bearings and clevis joints, flange bearings, spherical bearings and pillow block bearings. Self-aligning bearings are easy to mount, suit all angular variations and in many cases can be replaced by special housings.

The user of this systems avails of all the benefits of high-performance polymers. They have excellent vibration dampening properties, and are technically applicable in dry operation. They are insensitive to dirt, can operate in liquids and even in chemicals and are completely resistant to corrosion. The bearing elements are light and save installation space and costs: both in procurement and in operation by the saving of maintenance and installation costs.

igus® polymer bearing

But, there are still more basic advantages, says Richard Baumgartner:

"It's true that the material cost of polymer plain bearings is somewhat higher compared to cloth bearings, but the installation time factor reduces it by about tenfold. The installation is easier, which reduces the peripheral work. Moreover, there is the advantage of service life. A cloth bearing should be replaced three to four times. The savings accumulate in this case. The dismantling expenditure exceeds the material price by three to four times."