Oscillate and pivot with plastic bearings

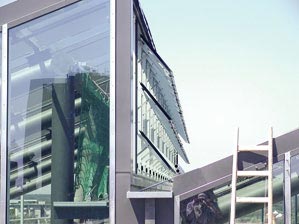

New glass lamellae system / Adjustable facade for the service center of an automotive manufacturer"Dematerialized construction" with filigree designs in steel and glass is a current trend in industrial architecture. To enable a "wellness climate" with high heat insulation in such buildings, innovative solutions are sought for mobile glass facades. Thereby, high requirements are posed not only to the creativity of the facade designer, but also to the applied bearings, as demonstrated by the example of the new glass lamellae system of the Fenster Keller GmbH & Co. KG in Neuenstein (FKN). This trend is applicable to a great degree for the presentation room of the automotive manufacturer. There is much in favor of steel-glass buildings: It generates a maximum of transparence and openness, and the external shop-window effect of the sales rooms and/or showrooms brings enormous benefits. Often however, particularly for large glass surfaces, a natural temperature regulation and an air exchange between the interior and the exterior is desirable. Moreover a partial opening of the facade should be provided during strong solar radiation, for otherwise the heat accumulates in between both facades and the building gets strongly heated up. This was exactly the job of FKN (Fenster-Keller Neuenstein) GmbH & Co. KG, who was assigned with the design and construction of the facade elements. As the demanding client desired a grand, "de-materialized" solution, a conventional profile frame was dropped. The panes should be executed without frame and at the same time had to be opened.

Modern optics and "wellness climate" in the interior: The facade with adjustable lamellae windows makes it possible.

The iglidur® bearings are in their element if such a property profile is involved. Originally developed for machine and plant construction, these bearings made of high-performance polymers also offer significant advantages to structural engineering, thus also in facade construction. They are lubricant-free and thereby almost maintenance-free; furthermore they are insensitive to dirt accumulation and resistant to corrosion. Even with high loads, constant coefficients of friction are attained in long-term applications. Plastic bearings are also economically satisfactory besides the technical advantages: Polymer plain bearings are considerably cheaper than the standard metallic roller bearings. The iglidur® program covers a very broad spectrum of various plastic compounds, so that the exact material can be chosen for the relevant application. iglidur® G is used for the facade drives of FKN. As an economical "allround bearing", it is well-suited for oscillating and pivoting movements with low to medium speeds, also at extremely high loads and under adverse environmental conditions - thus ideal for those application profiles for which the FKN project developers are seeking a solution. Moreover the iglidur® G is available from stock in a multitude of dimensions at any time.

The individual lamellae are continuously adjustable up to an aperture angle of 80°. The igus® bearings make up the bearing system of the lamellae in the drive system .

The test show that FKN made the right choice with the plastic bearings. Thereupon a total of 7300 iglidur® G bearings have been built in in the 63 supporting posts of the facade of the service center. Ever since they provide for a trouble-free, secure and reliable movement of the outer facade.