How bearings provide dynamics

Bearings in the packaging industryThe "Innopack CSM" (CarryStripMaster) of the KHS Maschinen- und Anlagenbau AG, Kleve, provides various types of packages with a carrier handle - starting with shrink packages with tins through PET bottles with and without contour up to tetrapacks and tray packages. An essential component makes up the highly dynamic, powered application head that should be as light and small as possible. The Innopack-CSM's application head, entirely newly developed by KHS, starts spontaneously according to requirement through a simple pressure sensor system and provides, in a minute, up to 70 packages with a carrier handle. The operation takes place in single-, dual- or three-track options - thus up to 210 packages are possible in a minute. In order to guarantee the essential high dynamics and position accuracy in the operation, the application head is subject to design criteria like "low weight" and "space saving" besides many other requirements such as:

According to the opinion of Tilo Lechner and Ludger Paul, in charge of the mechanical design and development of the "Innopack CSM" at KHS Kisters, plastic bearings and rod end bearings were indispensable: "There was no alternative to the plastic machine components, if the requirements specification with regard to weight, space and costs were considered. The decision for igus® as supplier made it easy for us. We have already worked together many times, and the company was always known to be innovative. Moreover the project monitoring is ideal."

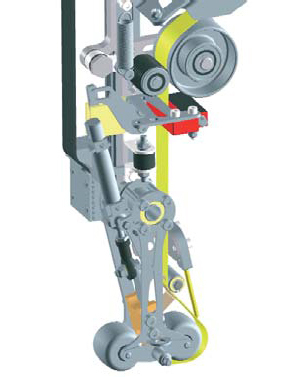

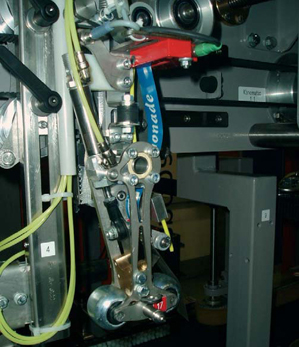

Application head of the company KHS

The application head now features several bearings applications; to take high loads and absorb impacts. On the one hand they have to find the pivotal point for the pressure sensor system and on the other, function as roller bearing. Thereby they are light on the scales and enable larger inner diameters (in the same space) than ball bearings.

igus® also accounts for other bearings from the iglidur® G family that are used by KHS in two positions of the application head. The economical allrounder withstands extremely high loads and functions in low to medium surface speeds. The self-lubricating effect makes them maintenance-free in dry operation, as well as insensitive to dust and dirt. Like all iglidur® bearings, the used high-performance material is composed of base polymer, fibers, fillers and solid lubricants.. The components take care that the coefficients of friction and specific wear are kept as low as possible.

iglidur® G bearings additionally feature a component excellent against chemicals. Most lubricants cannot harm them. The same applies to many weak organic and inorganic acids. iglidur® J is "the" material for the packaging industry due to its exceedingly low humidity absorption and the lowest coefficients of friction. In the "Innopack CSM", the specialist for fast and slow motions provides for very low coefficients of friction and the minimum stick-slip effect. It is recommended for applications with medium pressure loads - for high speeds and high wear resistance.

Application head of the "Innopack CSM" carrier handle dispenser