Control cable for extremely narrow bending radii

Machine and production downtimes have now come to an endThe Chainflex® CF98 control cable proves its capability in an international electronic company in Shanghai. The automated stacking unit for phosphorous screens here failed several times, because the control cable next to two air tubes was defective. The travel here amounts only to a meter with 300,000 double strokes per month. The space for the unit is conceivably small. The bending radius of the energy supply system is just 18 mm. After a very short operating time, the unit should be shut down several times to replace the cables. The cost of downtimes for eight stacking tables amounts to about € 6,600, which is a minimum of € 75,000 per year - an untenable situation if all cost-reduction potentials must be utilized in the electronics manufacturing. Since the installation of the Chainflex® CF98, there has been no more failure in the factory in Shanghai. The control cable increases the operational safety on a long term and lowers the costs.

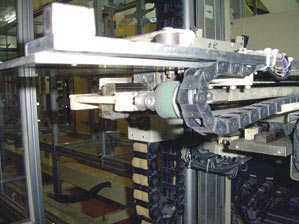

Shanghai, automated stacking unit for phosphorous screens: Square installation space, small bending radius, 300,000 double strokes per month pose high requirements on the control cable.

Energy supply systems are in the forefront of technology in mechanical and plant engineering and in the handling technology. Today even narrow bending radii do not pose any problems. Igus developed complete energy chain systems as answer to the multifaceted problems. Chainflex® cables and energy supply systems are offered as a single-source supply and according to application with system guarantee. The control cable Chainflex® CF98 plays off its strengths for instance in narrow installation spaces and corresponding bending radii.

Control cable for narrow bending radii