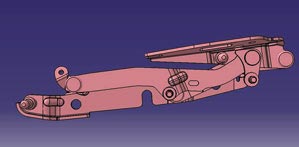

Multi link vehicle boot lid hinges

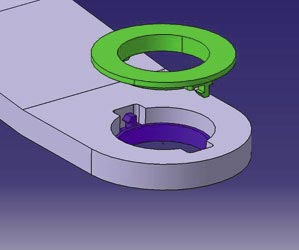

It was decided to explore the possibilities of a plastic bush and igus® was contacted to discuss the situation. Plastic bushes had previously been explored and one of the main problems was electrical conductivity. It was explained that bushes made from iglidur® RN89 had good electrical conductivity and would recalibrate during the e-coat process and that this could be a good starting point. Samples were manufactured and tests carried out. It was established that hinges could be built with a force of 20 newtons and after the e-coat process this reduced to 8 newtons with no significant loss in stiffness. Hinges were tested at -40 degrees and proved to show very little increase in torque. There were two problems that were highlighted during the test work. Firstly the life time tests, 30,000 cycle endurance with environmental exposure, mainly Arizona dust and salt water. The hinges failed at 10,000 cycles due to the bushes rotating in the housing. The housing holes are punched into 47 ® 3.5mm steel and therefore have a small amount of burr. If the bushes started to move in the housing this burr started to cut into the bushes until they were completely destroyed. This was temporally overcome by gluing the bushes into place; the hinges then passed the endurance tests and also various other tests, including water absorption, stiffness, lateral displacement and the effect of long term static loads. The customer additionally carried out these tests on vehicles in climatic chambers. Vehicles were also built and sent on long winter and summer test, involving approximately 8 weeks in cold and hot desert conditions. Secondly, the bushes fell out of the housing during the assembly process. This was overcome with the addition of gluing the bushes in to the holes, but this could not be a production route to take. An iglidur® bush was designed to stop the rotation and also clip together in the hole. The design is a simple bush that fits each side of a shaped hole that is quick and easy to assemble. The cost of the new bush design is slightly less than the current single steel backed bush and there are potential cost improvements with the assembly process.

Andrew Profitt

Product Design

ITW Highland UK