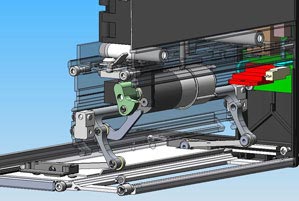

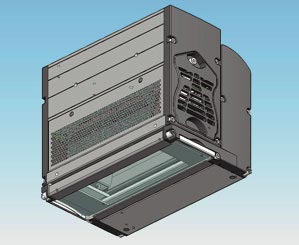

Fast acting DC motor driven mechanical shutter mechanism

for a UV lamp head operating on a digital inkjet platform

A production solution was required to replace the prototype joint design which was costly, timely to assemble, had low repeatability and suffered premature failure. The mechanism design needed to operate at speeds of 60m/s and have a service life of >15million reciprocation cycles. The pivot joints had to endure maximum dynamic loadings of approx 50N and maximum rotations of 180° at a velocity of 0.078m/s. Environmental operating temperature expected was 90°C max, in addition to indirect exposure to intense UV emissions. Other issues the design had to resolve were quality and reliability, ease of manual installation, reduced size, weight, maintenance and cost. The primary selection criteria for iglidur® J bearings were, in order of importance: cost decrease; size and weight reduction; performance enhancement; ability to cope with the environment; ease of assembly and availability from stock as a standard item. The iglidur®„ J bearing provided a controlled, light, press fit installation, giving the benefit of simpler pivot joint design of uni-direc- ® tional press and snap fit together. Assembly was made simpler and quicker without the need of special tooling. "The resulting design gave consistent reliability as well as reductions of 300% in cost and 400% in assembly time. Design is now in full manufacture."

Martin Wells

Mechanical Engineer

Integration Technology