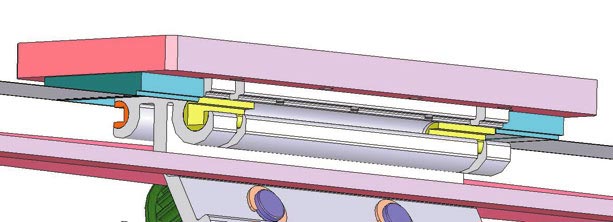

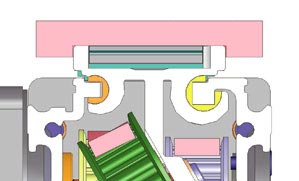

Zero backlash belt driven actuator

The Harmonic Linear Drive has a built in speed-reduction, equivalent to having a gearbox of up to 40:1, due to an innovative and patented topological layout of the belt. It has linear motion of 2.5, 5, 7.5 and 10mm per revolution of the input shaft. Unlike ballscrews, which are limited in the length of travel, this actuator can have strokes up to several metres with zero backlash. A low-cost guidance system can be obtained by using igus® plastic bearings in the actuator's extrusion. As extrusions may vary over their length, a bearing arrangement was required that would not be over-constrained and could tolerate deviations caused by defects in the extrusion, or by less than perfect mounting conditions. ® By using an iglidur® J bearing over a square feature in the extrusion section, vertical and horizontal motion is constrained, but the carriage is free to rotate. By using a DryLin® T replacement kit on the other side of the extrusion, this rotary freedom is constrained, but some lateral clearance allows for variations in the gap between the two features without over constraining the carriage. The two upper flat bearing surfaces provide a support for the edges of a seal tape that prevents the ingress of dirt.

Tim Jones

Managing Director

Harmonic Linear Drives Ltd. / Deddington Design & Development