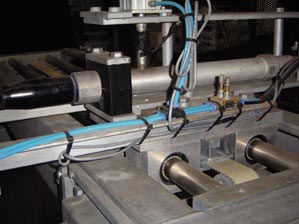

A machine slideway on a wet blast cleaning machine test bed

The carriage carries a blast nozzle and travels 1200mm under variable speed by a toothed belt drive in either direction. At the end of each run, the carriage is covered with water and abrasive. The problem was to devise a method for the carriage transport, without recourse to expensive shielding, concertina type guards etc., which would have to be very good indeed to prevent the fine water/abrasive mist from accessing the drive/slideway mechanism. The solution was to do away completely with any guarding and wash the complete machine down with water after every few runs. Only plastic bearings on stainless steel shafts could have done this job and the solution proved highly successful. DryLin® bearings from igus® were used in this application.

Michael Ratzer

Head of Research & Development

Farrow System Ltd.