Rugged, safe and UV resistant

Preassembled energy supply system for fairground ridesThere is hardly any application in which reliability of every part is as important as in the fairground rides. There wasn't even one break at the first drive operation at the end of October 2005 at the Bremer Freimarkt. The passengers of the "Wild´n´Wet" white-water ride are transported to the starting point at the top by an almost 20-meter high elevator. The raft ride is the first transportable fun ride for which the company Baasch & Didong GmbH based at Trier built an elevator. The elevator is moved by a drive system that executes a rotation as special feature. A difficulty arose in designing the energy supply system of the two moving platforms on which the nine passenger gondolas are incorporated. The power was supplied by two rugged and reliable, made-to-spec igus® energy chains of the E4/4 type, Series 3838, to the motors and to the hydraulic units on the two platforms. The demands on the facility are very high. All parts of the elevator are permanently exposed to wind and weather. Additional centrifugal forces act upon the parts by the 180° rotation. And finally everything should be removable and transportable in the shortest time.

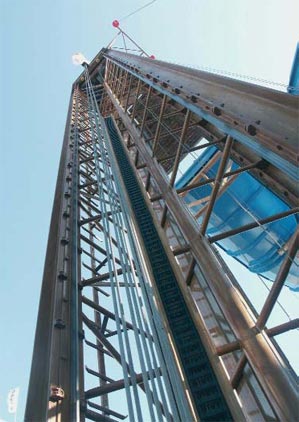

Energy chain on the elevator tower of the Wild´n´Wet

There is in fact a number of different reasons to opt for the preassembled energy supply systems in the automation of machinery and equipment. The manufacturing costs are reduced, and sources of defects are almost excluded. The project planning costs reduce and reliability rises. There are potential applications, among others, in installation engineering and handling technology, conveyance and storage, or in mechanical engineering.

The requirements of the overall system are defined on site together with the igus® field service employees. Then igus® produces an ideally assembled “ReadyChain®” energy supply system especially for the customer's needs – in this case: Trierer Aufzugbau Baasch & Didong GmbH. The chain itself is made of special plastic, which is light but almost indestructible. The E-Chains® not only stand up to the mechanical loads caused among other things by the fast movements, but also protect the cables in the chain from damage.

“The advice was outstanding,” says, Horst Baasch, a trained engineer, “the product was right, the deadline was right, as was the agreed price.” What more can you ask! When you can rely on an experienced system partner like igus®, you do not have to reinvent the wheel. ” Only a few weeks passed between the first enquiry with igus® and the delivery of the tailor-made “ReadyChains®”. In the meantime the igus® specialists assembled the E-Chains®. “It was important, for example, that the material used for the chain is UV-resistant and does not become brittle,” explains igus® consultant Jochen Weber. The rafting ride is namely exposed to constant sunshine outdoors. Normal plastic would soon become fragile. The same goes for the insulation on the power cables.

Whilst one elevator platform goes up with a gondola, the second one comes down. The assembled E-ChainSystem® gives protection and guides the power for the wooden transport belts on the platforms.

The ReadyChain® energy supply system in the fairground operations need to brave stresses ranging from extreme heat to frost. Even when it doesn't rain, the elevator gets continuously wet from the white-water ride The ReadyChain® E4/4 of the Series 3838 brings about a solution to counter the centrifugal forces arising from the 180° rotation. They incorporate the so-called tongue and groove, a design highlight that has been patented by igus®. While winding and unwinding, the front chain link catches on to the next respectively in the bend thus stabilizing it. In the "Wild´n´Wet" elevator two energy chains run in guide channels, which hinder the deflection of the chain during the rapid upward and downward movement with simultaneous rotation.

Satisfied with the premier of "Wild 'n Wet": (f.l.) Joachim Löwenthal, owner Daniel Löwenthal, igus® consultant Jochen Weber, Horst Baasch (Managing Director of Trierer Aufzugbau)

The ReadyChain® concept has quickly convinced the Trier-based elevator manufacturer. With the ReadyChain®, the customer assigns to igus® his entire procurement logistics, from the purchase of all essential special parts up to the provisioning of the ready-to-mount system on a fixed installation date, efficiently and safely.

There is a number of reasons to opt for the preassembled energy supply systems in the automation of machines and plants. The manufacturing costs, sources of error and the project planning costs are reduced, whereas the reliability is increased.