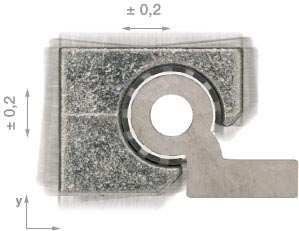

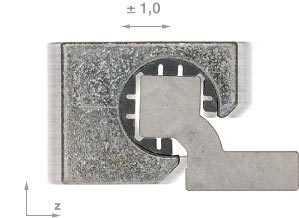

The user reduces installation costs with DryLin® WQ, the square profile. Floating bearing, selectable in all directions (+/1 mm), compensate for misalignments and parallelism errors between the rails. A seizure that otherwise is prevented only through an elaborate parallel alignment can be excluded.

Though DryLin® W is a profile rail system, it can compensate for rotation angle errors on the x-axis. An angle of +/- 7° is available for this. Twisting, as is known in sheet metal components, is effectively eliminated.

DryLin® W - Design tips and rules

Floating bearing, selectable in all directions (+/- 1 mm), compensate for misalignments and parallelism errors.

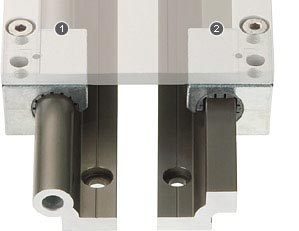

1. Fixed bearing, 2. Floating bearing

1. Fixed bearing, 2. Floating bearing

1. Fixed bearing, 2. Floating bearing

LL - round

LLY - angular

LLZ - angular

Rotating - angular

For application with two parallel guide systems, one side must be designed as floating bearing. There is a suitable fixed-/floating-bearing solution for every installation location, whether it be horizontal, vertical or lateral. This installation method prevents a sluggishness and/or a jamming of the guide with parallelism deviations between the guides. The floating bearing can be implemented by a controlled extension of the clearance in the direction of the estimated parallelism error. Thus an additional degree of freedom arises on one side.

During installation, take care that the floating bearing has the same clearance on both sides. You can see the version of the fixed/floating bearing system recommended by us in the designs given in the individual sections of the systems. The mounting surfaces of the rails and carriages should possess a good evenness (e.g. machined surface) to prevent twisting in the system. Smaller unevennesses in the mounting surfaces can be compensated up to a certain measurement by the floating bearing.

Automatic adjustment of parallelism errors,

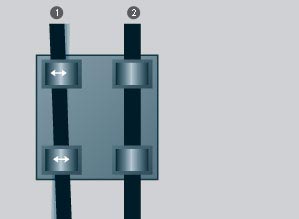

1. Floating bearing, 2. Fixed bearing

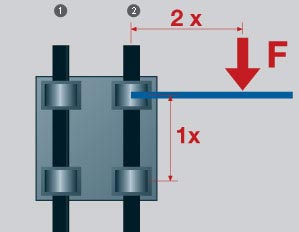

For the successful use of maintenance-free DryLin® linear bearings, it is necessary to follow certain recommendations: If the distance between the driving force and the fixed bearing is more than double the bearing clearance (2:1 rule), a static coefficient of friction of 0.25 can theoretically result in the seizure of the guide.

This principle applies regardless of the load or drive force. It is a product of friction and is always related to the fixed bearing. The greater the distance between the drive and the guide bearing, the higher the degree of wear and required drive force.

Failure to observe the 2:1 rule during the use of linear slide bearings can result in uneven motion or even system blockage. Such situations can often be remedied with relatively simple modifications.

If you have any questions on design and/or assembly, please make use of our applications consultancy.

The 2:1 rule,

1. Floating bearing, 2. Fixed bearing

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!