Positioning systems for electronics manufacturing

Low vibration, quiet, and low wear

The abrasion resistant fastening elements replace the conventional pin-hole connection For this reason, E6 is suitable for clean room application This was confirmed by the IPA Fraunhofer Institute, ISO Class 3*. The special structure of the chain link and the small pitches make the E6 system especially low noise. A measuring conducted by the TÜV Rheinland in May 2002 indicate a value of 46dB(A)** at a sound level caused by a minimum 10dB(A) of external noise. Another advantage of the fastener is that by the application of an electrically conductive material (igumid ESD on request), a continuous constant conductivity can be guaranteed. The following results can be obtained with standard material: ESD compatibility class 1 according to SEMI E78-0998 for Series E6.29.050.055.0

* according to DIN EN ISO 14644-1 for Series E6.29.050.055.0 for v = 1 m/s and v = 2 m/s

** Speed 2 m/s, 1.5 m unsupported, Series E6.52.10.100.0, 10dB(A)

Low vibration, quiet, and low wear

Extreme demands on availability and durability

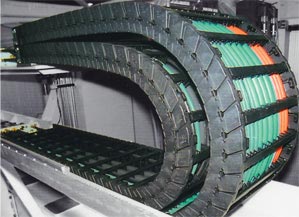

igus® E6 energy chains are used at Strohmann GmbH. High-speed sheet feeder makes high demands on energy supply.

No wear in the igus® energy supply system even in endurance tests. In a travel of 290 mm, a number of 50-60 cycles per hour is attained mostly in the three-shift operation.

The special structure of the chain link and the small division grant an extremely quiet and low-vibration operation of the chain.

Incidental grinding residues and the used oil cannot influence the energy supply systems.

The rail & Tracking systems are used wherever fast camera movements are an important factor as, for example, at sport competitions, but also at many popular events such as concerts, stage shows, etc.

Visible for approx. only one minute are these pictures, which are ”printed“ with UV lighton a light-sensitive screen.

The ”Virtu“ large-format printer can be used to print almost anything: sheetmetal, foils, textiles, wood, glass, and, of course, also paper in widths up3.5 metres.

The igus® E-Chain® E6 demonstrates its strengths inthe case of this cutting tool.

One igus® E-Chain® of the E6 family accelerates the work sequences in the case of this application for wafer handling in the chip production industry.

In this application, a two-spindle horizontal machining center was equipped with particularly silent and low-vibration energy supply systems.

Series E6.52.050.100.0 for especially quick transport of the cables and ink tubes in a digital printer, extreme low noise. Fill weight: 2 kg, speed: 2 m/s, acceleration: 20 m/s2, 6050 cycles per day

Series E6.52.150.150.0 in an automatic extraction system. Processed CD covers in the fraction of a second: Tool open, gripper on. Tool closed. All in 0.25 seconds, speed 8 m/s, acceleration: 78.5 m/s2

Horizontal and standing installation on the portal robot reduces noise level and vibrations.

E-Chain® lying on top of each other reduces vibrations and improves milling accuracy, Series E6.80