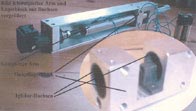

Development of a ball gripper

Rheinische Fachhochschule (technical college) in Cologne:Martin Karwowski, Dominik Böhme

Reduction of the friction when a camera arm is extended.

Longer grip with lubricant-free polymer bearings from igus®

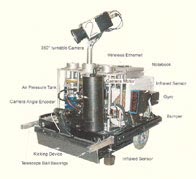

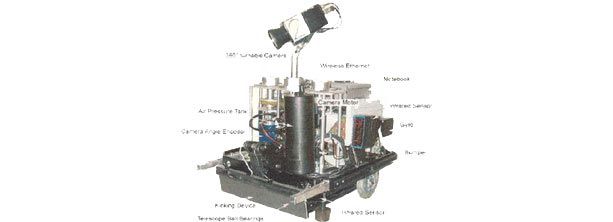

Martin Karwowski and Dominik Böhme developed the ball gripper in the scope of a project work for the Fraunhofer Institute for autonomous intelligent systems. The goal was to reduce the friction when the robotic arm is extended. The problem could be solved, the technical performance improved, the friction lowered and the service life extended by the use of igus® polymer bearings.

"An essential advantage compared to the traditional metal bearings is that the polymer bearings can operate without lubricants. Thus the regular maintenance can be avoided. Moreover, polymer bearings are cheaper to purchase and they even increase the cycle rate of the machine," says Martin Karwowski.