triflex® R 3D e-chain® specially made for robotic applications

triflex® R (R for "round") is the third generation 3-axis energy chains® from igus®. The multi-axis energy supply system triflex® R has been specially developed for the sophisticated 6-axis robotic applications in harsh industrial environments. Some of the important design features are: Fiber rod option for the partial reinforcement of the triflex® R, approximately +/- 10° .Torsion per chain link, high tensile strength through ball-and-socket joint. More than 100 components have been made available meanwhile in the triflex® R product range, so that all requirements can be covered from large welding robots up to the small pallet robots. triflex® R has received the iF design award.

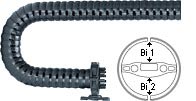

TRC = closed - closed version for protection of the cables against dirt and chips

Simplest installation and dismantling through the ball-and-socket system

Very simple filling - Just push in cable - easy system

Interesting applications from a variety of industrial sectors

Define cables, select chain and configure interior separation. Now also for all Triflex® R series!

Equipment support for various types of robots. Simplified ordering of complete systems.

TRC.30

TRC.30

Inner height Bi 1: 12 mm

Inner height Bi 2: 10 mm

Bending radius R: 50 mm

Pitch: 11.3 mm

TRC.40

TRC.40

Inner height Bi 1: 15 mm

Inner height Bi 2: 13 mm

Bending radius R: 58 mm

Pitch: 13,9 mm

Instructions for the joining and separating of the triflex® R - TRC.

TRC.60

TRC.60

Inner height Bi 1: 22,5 mm

Inner height Bi 2: 19,5 mm

Bending radius R: 87 mm

Pitch: 20,4 mm

TRC.70

TRC.70

Inner height Bi 1: 28 mm

Inner height Bi 2: 24 mm

Bending radius R: 110 mm

Pitch: 25,6 mm

TRC.85

TRC.85

Inner height Bi 1: 33 mm

Inner height Bi 2: 28 mm

Bending radius R: 135 mm

Pitch: 30,6 mm

TRC.100

TRC.100

Inner height Bi 1: 37.5 mm

Inner height Bi 2: 32.5 mm

Bending radius R: 145 mm

Pitch: 34.5 mm

TRC.125

TRC.125

Inner height Bi 1: 43,3 mm

Inner height Bi 2: 43,3 mm

Bending radius R: 182 mm

Pitch: 44,6 mm

Standard mounting bracket

for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection.

Light mounting bracket

Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection.

Standard mounting bracket

for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection.

Light mounting bracket

Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection.

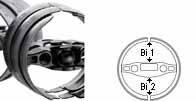

TRE.30

TRE.30

Inner height Bi 1: 12 mm

Inner height Bi 2: 10 mm

Bending radius R: 50 mm

Pitch: 11,3 mm

TRE.40

TRE.40

Inner height Bi 1: 15 mm

Inner height Bi 2: 13 mm

Bending radius R: 58 mm

Pitch: 13,9 mm

Instructions for the joining, separating and filling of the triflex® R - TRE.

TRE.60

TRE.60

Inner height Bi 1: 22,5 mm

Inner height Bi 2: 19,5 mm

Bending radius R: 87 mm

Pitch: 20,4 mm

TRE.70

TRE.70

Inner height Bi 1: 28 mm

Inner height Bi 2: 24 mm

Bending radius R: 110 mm

Pitch: 25,6 mm

TRE.85

TRE.85

Inner height Bi 1: 33 mm

Inner height Bi 2: 28 mm

Bending radius R: 135 mm

Pitch: 30,6 mm

TRE.100

TRE.100

Inner height Bi 1: 37,5 mm

Inner height Bi 2: 32,5 mm

Bending radius R: 145 mm

Pitch: 34,5 mm

TRE.125

TRE.125

Inner height Bi 1: 43,3 mm

Inner height Bi 2: 43,3 mm

Bending radius R: 182 mm

Pitch: 44,6 mm

Standard mounting brackets

for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection.

Light mounting bracket

Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection.

TRE.40.B

TRE.40.B

Inner height Bi 1: 15 mm

Inner height Bi 2: 13 mm

Bending radius R: 58 mm

Pitch: 13.9 mm

TRE.60.B

TRE.60.B

Inner height Bi 1: 22,5 mm

Inner height Bi 2: 19,5 mm

Bending radius R: 87 mm

Pitch: 20,4 mm

Instructions for the joining, separating and filling of the Triflex® R - TRE-B version.

TRE.70.B

TRE.70.B

Inner height Bi 1: 28 mm

Inner height Bi 2: 24 mm

Bending radius R: 110 mm

Pitch: 25,6 mm

TRE.85.B

TRE.85.B

Inner height Bi 1: 33 mm

Inner height Bi 2: 28 mm

Bending radius R: 135 mm

Pitch: 30,6 mm

TRE.100.B

TRE.100.B

Inner height Bi 1: 37,5 mm

Inner height Bi 2: 32,5 mm

Bending radius R: 145 mm

Pitch: 34,5 mm

Standard mounting brackets

for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection.

Light mounting bracket

Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection.

Assembly tool triflex® R B-version

Assembly tool for disassembly of triflex® R B-version

TRL.30

TRL.30

Inner height Bi 1: 12 mm

Inner height Bi 2: 10 mm

bending radii R: 50 mm

Pitch: 11,3 mm

Instructions for the joining, separating and filling of the Triflex® R - TRL.

Standard mounting brackets

for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection.

Light mounting bracket

Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection.

Instructions for the joining, separating and filling of the Triflex® R - TRLF.

Standard mounting brackets

for TRC / TRE / TRL. Also possible with strain reliefs and as intermediate connection.

Light mounting bracket

Standard for the TRL version. Also compatible with TRC / TRE; possible with strain reliefs and as intermediate connection.

Continuously adjustable retraction force

Infinitely adjustable retraction force for small robots

Universal module for all motions on the robot

Intelligent problem solution through directed pretension.

Offers the potential to mount the fiber rod module in the desired position on the robotic arm.

Secure mounting also in the use of cables with large cross section.

Available with and without swivel bearing

Well protected in extreme applications.

Protection against weld and metal spills up to 600°C

Special cables for long service life in robotic applications.

First choice for multi-axis industrial robots

Three versions are available: TRC: closed design; TRE: "Easy" design, very easy to fill in from outside; and TRL: the "Light" version, likewise with "easy" design

Universally applicable in general mechanical engineering

Secure energy supply system

Multi-axis (3D movements)

High torsional stability

Can be shortened and lengthened as required due to the individual elements

Large filling space

Doesn't get stuck in the interfering edges

Small bending radius

Simple cable routing for three-dimensional applications with ball-and-socket system for absorption of high tensile strength

Cables easy to install and replace (TRE/TRL version)

Fiber rod module for partial reinforcement and to give direction

TRL - One-piece element, extremely light

High tensile strength without additional elements like steel cables, spring elements, etc.

First choice for industrial robots

Machine tools

Handling equipment 6-axis

Material handling system

General mechanical engineering

iF-Design Award for "TRC"- and "TRL"-Design

Cleanroom environments on request

Series TRC electrically conductive ESD/TEX versions possible

UL94-V2classification

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!