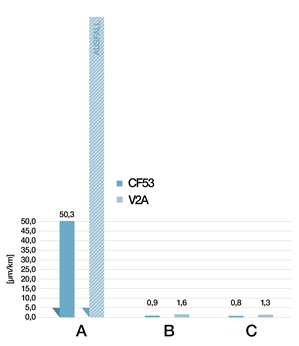

The coefficients of friction for our iglidur® J260-PF Tribo filament were low in all tests. On the other hand, the ABS material failed the rotating test on the stainless steel shaft.

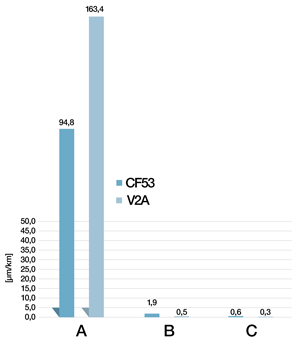

The printed plain bearings made from our Tribo filament had a similar wear resistance to our classic injection moulded parts on all test structures.

This means printed parts such as plain bearings and worm gears can be installed and put to use in industrial applications immediately.