iglidur® l3-PL for 3D printing with SLS

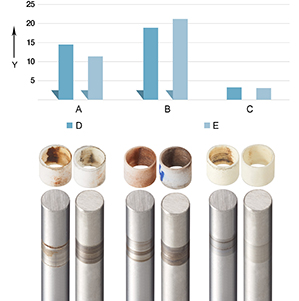

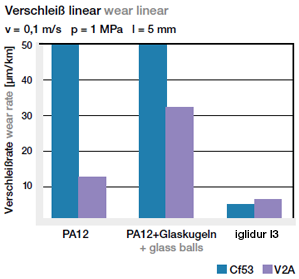

The material iglidur® I3-PL, specially developed for laser sintering, proved to have an abrasion resistance at least 3 times greater than conventional materials for laser sintering during tribologic tests in the igus® test laboratory. This means the degree of design freedom for abrasive loaded parts has been increased yet again.

For beta testing

wear-resistant

Good mechanical properties

Detail accuracy with exact surfaces

Processing similar to commercially available SLS materials

Typical applications:Prototype construction, small series, custom engineering, …

| Genera l features | |

|---|---|

| Colour | yellow | moisture absorption at 23 °C and 50 %r. h. | 0,5 weight-% |

| Maximum water absorption | 1,9 weight-% |

| Thermal properties | |

| Max. long term application temperature | +80 °C | Max. short term application temperature | +120 °C |

| Minimum application temperature | -40 °C |

| Ordering number | ||

|---|---|---|

| I3-PL-1000 | Upon request |  |

| More about selected part: | ||

3D-CAD Sample request

Sample request Quote request

Quote request Price list

Price list myCatalog

myCatalog

|

||

Upon request

Do you have any ideas or concrete task proposals for the SLS printing of abrasion loaded parts? Then please contact us.

More motion plastics® for 3D printing

3D printed Tribo filaments

Our tribologically optimised filaments are up to 50 times more abrasion-resistant than standard 3D print materials. This results in higher levels of effectiveness. So you can produce prototypes and small series more quickly and cost effectively. Printed components can also quickly replace wear parts and reduce downtime periods.

3D printing service

We print your customised component from lubrication and wear resistant iglidur® plastics; you can quickly install and use it. It’s very simple: whether a prototype or a complex custom part. Tell us your requirements, upload your 3D data or choose from our CAD file. Depending on its complexity, we will then deliver your product in as little as 24 hours.

3D print building

We have compiled the most suitable and popular products for you from our diverse kits: linear guide systems and energy supply systems with low installation heights, the smallest sizes and the narrowest bending radii. Our lubrication and maintenance free 3D printing components allow you to improve your 3D technology while also reducing costs.

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!