Wear of machine parts depends on diverse influence factors. Thus designers are often confronted with the challenge of deciding between various material alternatives. With regard to wear behavior, igus® has now also compared its bar stock material iglidur® A160, as well as its tribo tape material iglidur® V400 on various counter partners with PTFE foils.

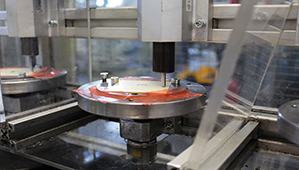

The trials were executed under the following test parameters:

Foils: iglidur® A160, iglidur® V400, and PTFE

Counter partners: Stainless steel, glass (in this case: Soda-lime glass, PET, and paper

Load: 10 N

Speed: 0,22 m/s

Temperature: 23℃