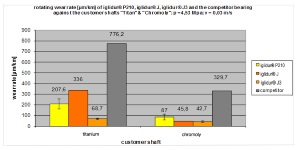

Result:

The iglidur® J3 bearings have the lowest wear rate on both shaft materials (36.6 μm/km to 73.3 μm/km). These were the best test scores in the test. In contrast, the plain bearings of the competitor material wear out on both shaft materials at rates of 329.7 μm/km to 776.2 μm/km.