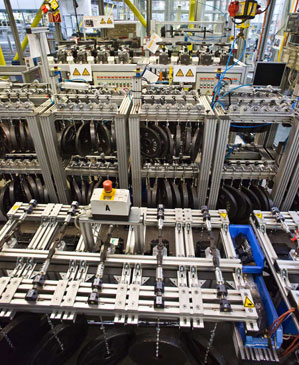

Specially developed for fast continuous operation under low loads, iglidur® L500, inter alia, is intended for fan and electric motor applications.

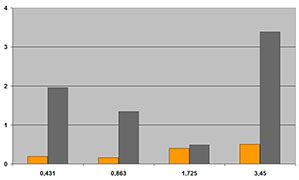

The newly developed iglidur® L500 was compared with a sintered bearing in the igus® laboratory. The aim was to determine the wear rates at various gliding speeds.

The comparison took place under the following test parameters:

Rotating wear against cf53

P = 0,25 MPa

T = 23°C

Duration = 24 h

Plain bearing: iglidur® L500, sintered bearing