Flip through

| … one material - from prototype to series … |

| iglidur® stock bar news and line extensions 2015 |

iglidur® 3D printing service: Ordering online – now with price calculation

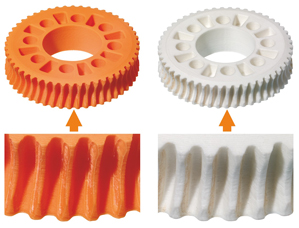

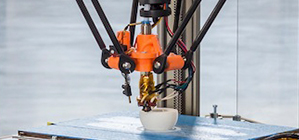

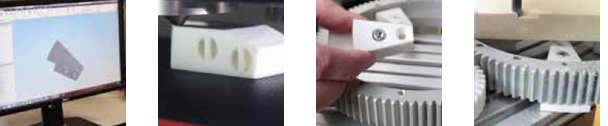

We print your customised component from lubrication and wear-resistant iglidur® plastics; you can quickly install and use it. It’s very simple: whether prototypes or plain bearing custom parts – with the additive production technology, the design freedom is almost endless. Even complex shapes can be generated at a low cost by working with two different plastics: either the support material disintegrates or the component is created from the conventional ABS print material and the glide surfaces from our abrasion-resistant iglidur® high-performance polymers.

Send us your request, upload your 3D data or choose from our CAD file. Depending on its complexity, we will then deliver your product from 24 hours.

The benefits of the 3D printing service

Receive prototypes and custom parts more quickly

Use the latest technology without having to make investments

Print parts from abrasion and wear-resistant iglidur® materials

Tribological printed parts specially for moving applications

Start by testing products, then order large quantities

You can choose between four different iglidur® tribo filaments

iglidur® J260-PF

Available in yellowGreater chemical resistance and higher upper application temperature, one material from the prototype to series production

iglidur® I180-PF

Available in white and blackExcellent wear and abrasion properties, high strength and elongation at break

iglidur® I170-PF

Available in yellowEven better wear resistance, higher workmanship standards demanded

Four online steps to a customised 3D printed part

How does the printing service work?1. Give us the information concerning your desired 3D printed part, special requirements, etc. and send us your 3D model (ideally STEP) by e-mail or via the upload area on the website.

2. We will send you a quotation for your component; made from our 3D tribo materials.

More motion plastics® for 3D printing

3D printed Tribo filaments

Our tribologically optimised filaments are up to 50 times more abrasion-resistant than standard 3D print materials. This results in higher levels of effectiveness. So you can produce prototypes and small series more quickly and cost effectively. Printed components can also quickly replace wear parts and reduce downtime periods.

3D printing material for laser sinters

The material iglidur® I3-PL, specially developed for laser sintering, proved to have an abrasion resistance at least 3 times greater than conventional materials for laser sintering during tribologic tests in the igus® test laboratory.

3D print building

We have compiled the most suitable and popular products for you from our diverse kits: linear guide systems and energy supply systems with low installation heights, the smallest sizes and the narrowest bending radii. Our lubrication and maintenance free 3D printing components allow you to improve your 3D technology while also reducing costs.

iglidur® - Printed components in test

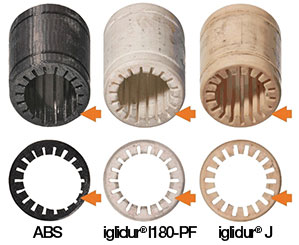

Wear comparison linearPrinted components made from iglidur® materials are more wear resistant and therefore more durable than those from the standard print material ABS. Printed iglidur® parts are the only ones to offer impressive performances in moving applications.

| material | Wear rate [µm/km] |

|---|---|

| Commercially available ABS (printed) | 13,3 |

| iglidur® I180-PF (printed) | 0,8 |

| iglidur® J (moulded) | 0,2 |

| material | ABS printed | iglidur® |180-PF printed |

| Torque | 1,2 Nm | 2,9 Nm |

| Run time | 75 h | 140 h |

From 24h

iglidur® I180-PF immediately

iglidur® l180-BL as of November

iglidur® I170-PF immediately

iglidur® J260-PF immediately

as of november