Versatile liner: the first iglidur® tribo-tape

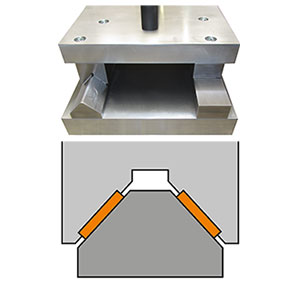

The tribo-tape liner from igus® can be used to line a variety of tribologically stressed surfaces and shapes to optimise transportation tasks, for machine beds, etc. With a thickness of only 0.5 mm (including 0.65 mm adhesive back), the space requirement is very low. The easy workability (the tape can be cut using scissors) and optional self-adhesive back on the liner result in almost unlimited possibilities for use.

Lubricant- and maintenance-free

Easy to cut

Adherent

Suitable for the smallest installation spaces

Typical applications:Mechanical engineering, materials handling, fixture construction, installation technology, etc.

Liner material: iglidur® A160

Low coefficient of friction

Best wear-resistance

Upto +90 °C

Compared to similar thin liners, the cost-effective iglidur® A160 tape has a very high wear resistance.

Liner material: iglidur® V400

Extremely wear resistant

Highly resistant to media

Upto +200 °C

Tests have shown the extremely wear-resistant and highly media and temperature-resistant iglidur® V400 tape to be up to 10 times more wear resistant than special products for machine beds and the like.

The iglidur® tribo-tape liner is also available with a self-adhesive back for quick and easy installation. With a self-adhesive back, iglidur® A160 can be used at temperatures of up to 70°C and V400 at temperatures of up to 170°C.

Wear rotating against stainless steel pin (1.4305)

F= 35 N, v= 0.5 m/min

Y = Wear/mass decrease [mg/km]

A = polycarbonate (PC)

B = compound liner

C = polyetheretherketone (PEEK)

D = polyetheretherketone (PEEK) mod. 1

E = polyetheretherketone (PEEK) mod. 2

F = polyethylene terephthalate (PET)

G = iglidur® A160

|

Part No.: |

| Part Number | Film thickness | |||

|---|---|---|---|---|

| A160-T-005-0020 | 0.5 | - | Upon request |  |

| A160-T-005-0050 | 0.5 | - | Upon request |  |

| A160-T-005-0020-G1 | 0.65 | with adhesive back | Upon request |  |

| A160-T-005-0050-G1 | 0.65 | with adhesive back | Upon request |  |

| A160-T-005-0100-G1 | 0.65 | with adhesive back | Upon request |  |

| A160-T-005-0120 | 0.5 | - | Upon request |  |

| A160-T-005-0500 | 0.5 | - | Upon request |  |

| A160-T-010-0500 | 1 | - | Upon request |  |

| A160-T-010-0500-G2 | 1.15 | with adhesive back | Upon request |  |

| More about selected part: | ||||

3D-CAD Sample request

Sample request Quote request

Quote request Price list

Price list myCatalog

myCatalog

|

||||

Liner: iglidur® tribo-tape V400

Delivery program:|

Part No.: |

| Part Number | Film thickness | |||

|---|---|---|---|---|

| V400-T-005-0120 | 0.5 | - | Upon request |  |

| V400-T-005-0120-G2 | 0.65 | with adhesive back | Upon request |  |

| More about selected part: | ||||

3D-CAD Sample request

Sample request Quote request

Quote request Price list

Price list myCatalog

myCatalog

|

||||

Adhesive back

G1 = temperature -20°C to +70°C

G2 = temperature -40°C to +170°C

width [mm]

thickness [mm]

Tape

iglidur®-Material

| Genera l features | Unit | iglidur® A160 | iglidur® V400 | test method |

|---|---|---|---|---|

| Density | g/cm³ | 1,0 | 1,51 | |

| Colour | blue | white | ||

| Max. humidity absorption at 23°C/50% R. H. | Wt.-% | 0,1 | 0,1 | DIN 53495 |

| Max. water absorption | Wt.-% | 0,1 | 0,2 | |

| Coefficient of surface friction, dynamic, against steel | µ | 0,09 - 0,19 | 0,15 - 0,20 | |

| pv value, max. (dry) | MPa x m/s | 0,25 | 0,5 | |

Mechanical properties |

||||

| Bending E-module | MPa | 1.151 | 4.500 | DIN 53457 |

| Tensile strength at +20 °C | MPa | 19 | 95 | DIN 53452 |

| compressive strength | MPa | 37 | 47 | |

| Maximum recommended surface pressure (20° C) | MPa | 15 | 45 | |

| Shore D-hardness | 60 | 74 | DIN 53505 | |

Physical and thermal properties |

||||

| Max. long term application temperature | °C | +90 | +200 | |

| Max. short term application temperature | °C | +100 | +240 | |

| Minimum application temperature | °C | -50 | -50 | |

| thermal / heat conductivity | [W/m x K] | 0,30 | 0,24 | ASTM C 177 |

| Coefficient of thermal expansion (at 23° C) | [K-1 x 10-5] | 11 | 3 | DIN 53752 |

Electrical properties |

||||

| Specific forward resistance | Ωcm | > 1012 | > 1012 | DIN IEC 93 |

| Surface resistance | Ω | > 1012 | > 1012 | DIN 53482 |

| chemical resistance | iglidur ® A160 | iglidur ® V400 |

|---|---|---|

| Alcohols | + | + |

| Hydrocarbons | + | + |

| Greases, oils without additives | + | + |

| Fuels | + to 0 | + |

| Diluted acids | + | + |

| Strong acids | + | + |

| Diluted bases | + | + |

| Strong bases | + | - |

| Radioactive rays [Gy] to | 1 x 105 | 2 x 104 |

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!