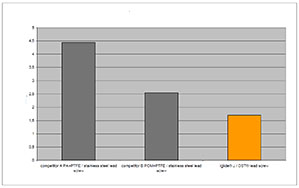

The wear comparison was carried out under the following test parameters:

Load: 200 N

Rotation speed: 100 rpm

Stroke lengths: 140 mm

Experimental temperature: ~23°C

PA+PTFE on stainless steel, POM+PTFEon stainless steel, iglidur® J on stainless steel

Thread pitch: DS10x25, 3/8“-1“

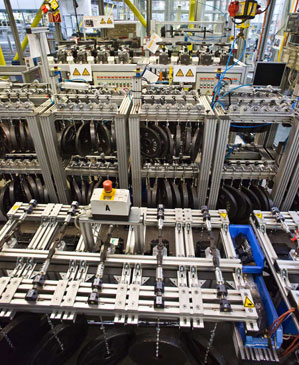

drylin® screw drives

drylin® screw drives