“Our technical centre in Cologne aligns our high-strength cables with our plastic energy chains in such a manner that these meet the necessary levels of operational reliability in real-life applications”, stated Rainer Rössel, head of the chainflex® cables division at igus® GmbH. The winners of this situation are the customers in all sectors, who can rely on the results. “They can always enjoy good peace of mind as our products meet all quality standards and guarantee long-term operational reliability and a long service life.” “

Numerous test series take place in parallel to usage under the toughest conditions, i.e. generally real-life ones. They simulate push and pull forces, friction values, wear, drive forces, bending forces and abrasion under the broadest range of conditions and speeds. Influencing factors such as dirt, weathering, low temperatures or impacts and shocks are also considered. No cost or effort is spared in systematically conducting the igus standard tests. The tests run continually for up to 365 days and are carefully monitored to provide demonstrable results. “We also invest great sums in material development in order to find materials for the future”, commented Rainer Rössel.

Good test results

Cables for 400 million strokes in ultra-fast pick-and-place movements

In today’s world, coordinated, assembled energy chain systems are already the norm in many machines, vastly enhancing the operational reliability of entire processes. The cables play an extremely important role in this regard. Extensively tested in the in-house laboratory and subjected to long-term studies, they are a key component for meeting the ever increasing requirements. New cable designs are constantly developed that have to meet the ever greater requirements in the world of semi-conductor assembly.

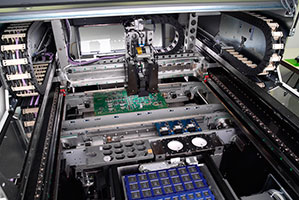

A line is generally made up of the three modules iFlex T4, T2 and H1. A look at the interior workings of the pick-and-place machines. (Picture: Assembléon)

The igus® in-house laboratory, with a size of 2,750 m2 and over 50 testing systems with not only long travels of over 120 m but also an 18 m long climate chamber, 6 g acceleration systems and robots from a broad range of manufacturers, is currently subjecting around 700 chainflex® cables to multiple different series of tests. The focus does not only lie on new products; previously tried-and-tested cable types are also regularly subjected to special, ongoing quality tests and specific customer requirements are reviewed.

All test results are recorded in databases. Growing by the year, this data pool provides precise and reliable information about actual service lives and acts as a basis for product development. The test data for energy chains and cables, as well as fully assembled systems, is so detailed that functional guarantees can be provided for the energy chain systems depending on their usage.

Assembled energy chain systems and high-strength special cables ensure the functional reliability of the pick-and-place machines. 400 million strokes are required. (Picture: Assembléon)

The procedure is always the same. Cables are almost always tested with a bending radius that is 30 to 50 percent smaller than that specified in the catalogue. Between 1 and 10 million reverse bends are conducted as a minimum. During the movement test, the electrical performance of the cables is constantly monitored using in-house-developed measuring systems. This makes it possible to detect the start of failures at an early stage.

When the cable is subsequently inspected, it has to be fully intact; in particular, none of the individual wires can be broken. Newly developed cable types are subjected to reverse bending in the energy chain for far longer periods before approval is granted for a new chainflex® series.

The company Assembléon Netherlands B. V. has developed a new generation of fully automated, iFlex T4, T2 and H1 series pick-and-place systems with a vision system. These can be used for small or large series. The SMD assembly occurs using robots on one or both sides in series quality for components from a size of 0402. Between 51,000 (T4) and 12,000 (H1) parts are handled per hour. The acceleration and speed are 35 m/s2 (y-axis) and 20 m/s2 (x-axis) and 2 m/s and 1.5 m/s respectively. The components require a service life of 400 million cycles, which equates to around seven years of continuous operation.

Electronic components are assembled from a size of 0402.

“Not only is high assembly accuracy required but so is the right process flow. There must be no wastage and no system downtime”, commented Project Manager Franks van Eldijk in explanation of the requirement profile. The company has therefore opted for igus system expertise. The pick-and-place machines use pre-assembled energy supply systems that have been specially tailored to the customer’s requirements. To ensure long-term functional reliability, the standard energy chain has been equipped with an interior separator especially optimised for this application and made from a special material. In combination with the jacket material of the cables, which is in turn aligned with the gliding material in the chain, there is no abrasion. The additionally used, specially developed cable and jacket materials also ensure that electrical requirements are fulfilled so as to easily meet the overarching aims of the system – durability, stability, functional reliability and a long service life.

The entire system is supplied ready for installation, with strain reliefs, connectors and machine mounting parts made from stainless steel and carbon. Only the final assembly takes place on site. During this process, all cables are installed in the functional end positions in such a manner that it is no longer necessary to adjust the cable length in the energy supply system on site. Work specifications and extensive documentation during production as well as assembly tools and a quality assessment in Cologne guarantee the perfect condition of every system.

“The movements in the pick-and-place machines are high in number and extremely rapid”, Rainer Rössel once again emphasised. Cables are often the weakest link in this demanding environment and have to function correctly over the long term. To guarantee stability, they have to be designed and manufactured tailored to the energy chain system. This occurs using state of the art technology – validated through extensive tests. Two proprietary test systems that can simulate the specific requirements of pick-and-pack machines have been installed in the igus® test laboratory. In addition to high lateral acceleration speeds, the cables are also redundantly tested in duplicate in three different radii and constantly monitored.

Marcel Lamers (igus® GmbH), Frank van Eldijk, Roy Brewel (both Assembléon), Rainer Rössel

“This firstly provides us with information about what happens under higher load values than those that exist in reality and secondly simulates the original output values in parallel”, stated Rainer Rössel. “These test machines, which have been running since 2010 and test the cables for the pick-and-place machines around the clock, give us clear information about the service life and any necessary preventative servicing measures.” But the benefits do not end there: “We can also take occasional cables and inspect them in closer detail without having to re-start the tests from the beginning again.” “

The whole range of available chainflex® cables is used in the pick-and-place machines – from motor, measurement system and data cables through to camera cables. There are at least twelve cables, all of which have been specially manufactured for the Dutch company. The braid structure is tailored to the bending radii, the conductor material is a special proprietary development and even UL requirements can be fulfilled. igus® has a clear market advantage in relation to all developments: “We are the plastic specialists. This also particularly benefits the cables. This is because we are the only provider who develops both products in-house, aligned to one another, thus enabling comprehensive testing. As far as I know, our laboratory is the world’s largest test laboratory for moving cables. And it is now also being used by more and more external customers, who do not have these capacities”, commented Rainer Rössel.

The plastic specialist has made great advances in developing these special cables. New tools had to be created for the interior separation although the quantities are to date still reasonable. Materials are also required for the special cables, which are extremely expensive to procure. “We are currently testing four possible materials in eight different set-ups. The medium-term aim is to develop an alloy material that is more stable yet also costs less. The initial results are highly promising”, the Divisional Manager reported. “If we can clearly reduce the cost of the cables in the near future, our development costs will be quickly amortised.”

The Dutch company has at no point regretted its decision to use the pre-assembled energy chain systems. “We used to use hybrid flat cables”, commented Frank van Eldijk. “However, these are no good in the pick-and-place machines as, especially within the scope of new product developments, changes always involve extremely high costs.” Chain-compatible cables, on the other hand, can be replaced quickly and easily so the entire system can be swiftly made available again in line with the known technical specifications.

The entire system is supplied ready for installation, with strain reliefs, connectors and machine mounting parts made from stainless steel and carbon. Work specifications, documentation, assembly tools and a quality assessment guarantee the perfect condition of every system.

“We use an excellent quality management system, are certified in this regard and meet the requirements of our customers, for whom we want to be a professional partner and supplier at all times”, Rainer Rössel clarified. “We constantly review our own development and production processes as this is the only way to ensure that we manufacture products of the highest quality and constantly develop solutions that meet both today’s requirements and those of the future. “

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!