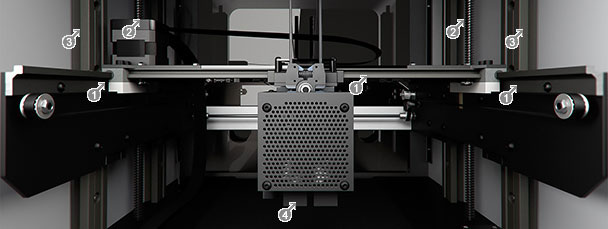

In addition to its generous installation space, the Cobot 3D impresses with its innovative design. The one-piece aluminium chassis encloses the printing space, and all mechanical components are fastened in the interior. The reduction to a few failure-proof components facilitates fast assembly, an affordable price, and also ensures premium quality 3D printing results.

drylin® linear technology in the Cobot 3D printer. Light, quiet, and completely lubricant-free

drylin® linear guides in the Cobot 3D printer are an ideal support for the concept

The linear guides of the drylin® T and W type series, and the drylin® SD lead screw units travel completely lubricant-free. This eliminates the risk of contaminating the housing, the filament, and the print result. The maintenance-free operation also increases operational reliability. Due to the drylin® N flat guide, placing the unit back into service after changing or maintaining the extruder head or the nozzle size is accomplished quickly and easily.

In addition to their low weight and the use of plastic and corrosion-resistant, coated aluminium, the guides from the drylin® type compel with their very quiet and accurate operation due to the "gliding instead of rolling" principle.

Go to applied products here

xy axis

xy axis

Z axis

To the manufacturer's website

More applications from different sectors can be found here

Go to manus® contest