Camping without lubricants

Highly compact while traveling, very spacious at the campground: this highlights the central characteristic of the "Zoom" camper prototype, which was designed and built by Ross Design GmbH. Its bunk slide out can be extended by 1.32 metres for a total of 5.22 metres, but this RV also features other real innovations. The lead screw modules from the drylin® series from igus® do their share toward this.

An RV that grows in length from 3.90 metres to 5.22 metres

As the name "Zoom" suggests, this concept, initially conceived by Martin Ross on the CAD computer and then put into practice, has a mobile component, wherein this description is rather an understatement.

While on the road, the "Zoom" is only 3.90 metres in length, making this camper truly a compact RV. After arriving at the campground, the camper uses an electrical motor to conveniently extend the entire sleeping quarters beyond the trailer hitch. It therefore not only gains 1.32 metres in usable length, but also an extension with a large double bed (1.60 x 2.05 metres) that does not interfere with the seating arrangement or the kitchen

Designing such a solution not only calls for an innovative idea, but also for the ability to implement it down to the last detail. And one needs to know suppliers who can provide the necessary components. As it relates to the load-bearing structure, the installations, and the entire RV interior, Ross Design has the necessary know-how in-house. For the company is part of Vöhringer Group, who is among the leading suppliers of RV and camper interiors, with activities that involve a variety of value-adding processes on wood and polyurethane (PU).

The majority of components on the "Zoom" are made in-house. But the drive and guide system for extending the slide-out are sourced from external suppliers. With respect to linear systems, Ross not only works together with igus® on the "Zoom", where it uses a three-point drive. Martin Ross: "The drive is centered under the extendable unit; two aluminium profiles installed above the slide-out are used as the guide. This prevents misalignments. “

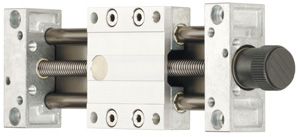

A lead screw module of type drylin® SLW is used as the central drive. These linear axis with trapezoidal threads (also available with high helix threads and toothed belts) do not need lubrication because the lubricant is incorporated into the gliding and guide elements, which are made from iglidur® J materials. Together with the hard-anodised aluminium shaft, these elements make an outstanding glide pairing.

drylin® SLW linear axis are easily integrated into the surrounding structure. They are compact in design, and provide a high level of torsional stability. The drive can be operated with a hand wheel or a motor. At the trade fair, this task was accomplished with a battery-powered screwdriver for demonstration purposes. An electrical motor from the comprehensive igus® product range is recommended for series production. Motors from other manufacturers are easily connected with the accessories also available from igus®. The aluminium guides Ross Design uses for the "zoomable" bunk section are also part of the igus® product range.

But the extendable slide-out is not the only innovation on the "Zoom". The new kitchen concept is equally ingenious. It is located aft and can be easily converted into an open-air kitchen by swinging open the large rear hatch. But the astute reader will think "hold on a minute - how will somebody operate the kitchen from the outside when it is located significantly above working height?" “

This is quite true. But Ross Design developed a movable kitchen block that travels vertically on two side-mounted lead screw axis. Anybody who wants to cook outside – "and camping is typically an outdoor event" as noted by Martin Ross –, can simply move the kitchen down a few steps. Moreover, bikes and canoes can be loaded through the large rear hatch when the kitchen block is fully moved to the top.

Here again, igus® lead screw drives of type drylin® SLW facilitate the required travel. However, this involves two lead screw drives operated in parallel on each side of the kitchen block that are synchronised by a control. In this case, Martin Ross relied on a proven drive kit from the automotive industry: after all, the two wipers on the windshield also move synchronously.

Ross Design is essentially not only the designer, but also the think tank of Vöhringer Group. "Based on these concepts, our objective is to present unconventional solutions for future camper generations to recreational vehicle manufacturers, and to demonstrate what can be accomplished with modern materials and modern technology. “

Some of these ideas involve the intelligent use of materials, others – and these are the key innovations of the "Zoom" – involve motion and variability. The fact that the designers relied on igus® components was ultimately a matter of chance. Martin Ross: "Three years ago, we were looking for a slewing ring bearing for the swivel joint on a new camper kitchen. I found igus® on the Internet and contacted them."

The steps that followed were nothing short of astonishing to the prospect: "Instead of sending us several brochures, we were visited by the assigned field sales representative igus®, who came by to determine what our needs were, and then provided us with the components. " Martin Ross greatly values this type of collaboration: "We like to work the same way – prompt, and without all the red tape. Because we work as a very small team, we also do not have the time to extensively address purchasing and administrative issues. The fact that the prices for bearings and drive elements are published in the Internet is also very helpful. " And the collaboration has become even faster since Adrian Belke assumed igus® field sales activities in the far southwest corner of Germany: Belke essentially lives "right around the corner".

But from Ross Design's point of view not only the level of collaboration, but also the components themselves are a good match. Martin Ross: "For us, the igus® products are ideal, because they are cost-effective, corrosion-resistant, and maintenance-free. " This is not only true for the plain bearings and linear drives. Ross Design has also used energy chains from the igus® product range in other prototypes.

On the "Zoom", the slide-out can be extended beyond the trailer hitch, turning the camper into a space miracle.

Cozy and spacious: the bunk does not interfere with the seating arrangement or the kitchen.

The extension is accomplished with a drylin® linear unit that is installed underneath the slide-out.

The lead screw modules of type drylin® SLW are compact in design and do not need to be lubricated because of the incorporated lubricant.

Aluminium guides made by igus® are located above the slide-out and provide a torsion-free three-point guide for the "zoomable" bunk section.

The height-adjustability of the kitchen block is accomplished with two synchronously driven lead screw drives with igus® linear modules.

Martin Ross (left) is not only satisfied with igus® products, but also with the level of collaboration. Alexander Mühlens (right), responsible for technical sales in Baden-Württemberg for igus®.

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!