An igus® customer uses the iglidur® all-rounder iglidur® G on galvanised shafts in a pivoting movement and would like to increase the lifetime of the application. Since galvanised shafts are not common nowadays and are not tested as a standard at igus®, igus® procured the shafts quickly to perform separate tests in the igus® tribological laboratory.

With such customer-specific tests, we would very much like to support our customers on a regular basis in making a well-grounded service life prediction and material preselection even in cases of unusual application parameters before the customers undertake their own (practical) tests.

In this case, the iglidur® material experts selected eight candidate materials for the test, including a brand new igus® material development which is not yet available in the market.

The bearing/shaft pairing decides: Service life optimisation on galvanised shafts

Three materials with partially very different characteristic profiles thus achieve an improvement compared to iglidur® G. Thereby, the heavy-duty material iglidur® Q and also the new development NMG1-848 performed best by far with a stress of 26 MPa, which we place in the medium load range, even if the predominant proportion of the typical plain bearing applications show still significantly lower radial loads. A service life increase up to factor 4 seems possible here.

The material experts were spot on with their preselection, and the use of an entirely new, not fully tested material, also pointed in the right direction. Even with the 45 iglidur® materials currently in the catalogue, the material development advances constantly and new improvements can be achieved.

At present, the customer performs his own tests based on these findings, in order to make a change in material after considering all aspects. For the igus® professionals, the following insight proved right once more: When optimising the service life of a bearing point, the shaft material is of crucial importance! – Both the material ranking and the absolute wear rates can change considerably depending on the shaft.

Conclusion:

For the igus® professionals, the following insight proved right once more: When optimising the service life of a bearing point, the shaft material is of crucial importance! – Both the material ranking and the absolute wear rates can change considerably depending on the shaft.

Do you also have an application with an "unusual" shaft? – We would be happy to test and determine the most durable iglidur® material for your application.

Just use the contact form!

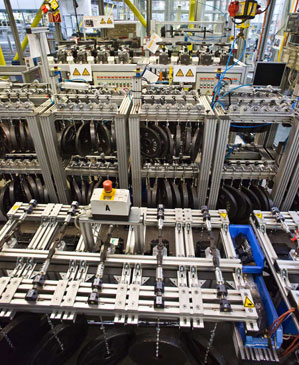

dry-tech® test laboratory

In the dry-tech® test laboratory, over 135 trillion test movements are executed every year

More than 100,000 products available! Delivery and consultation Mon-Fri from 7am-8pm and Sat from 8am-12pm!